Product Range

Looking for products

Find a product

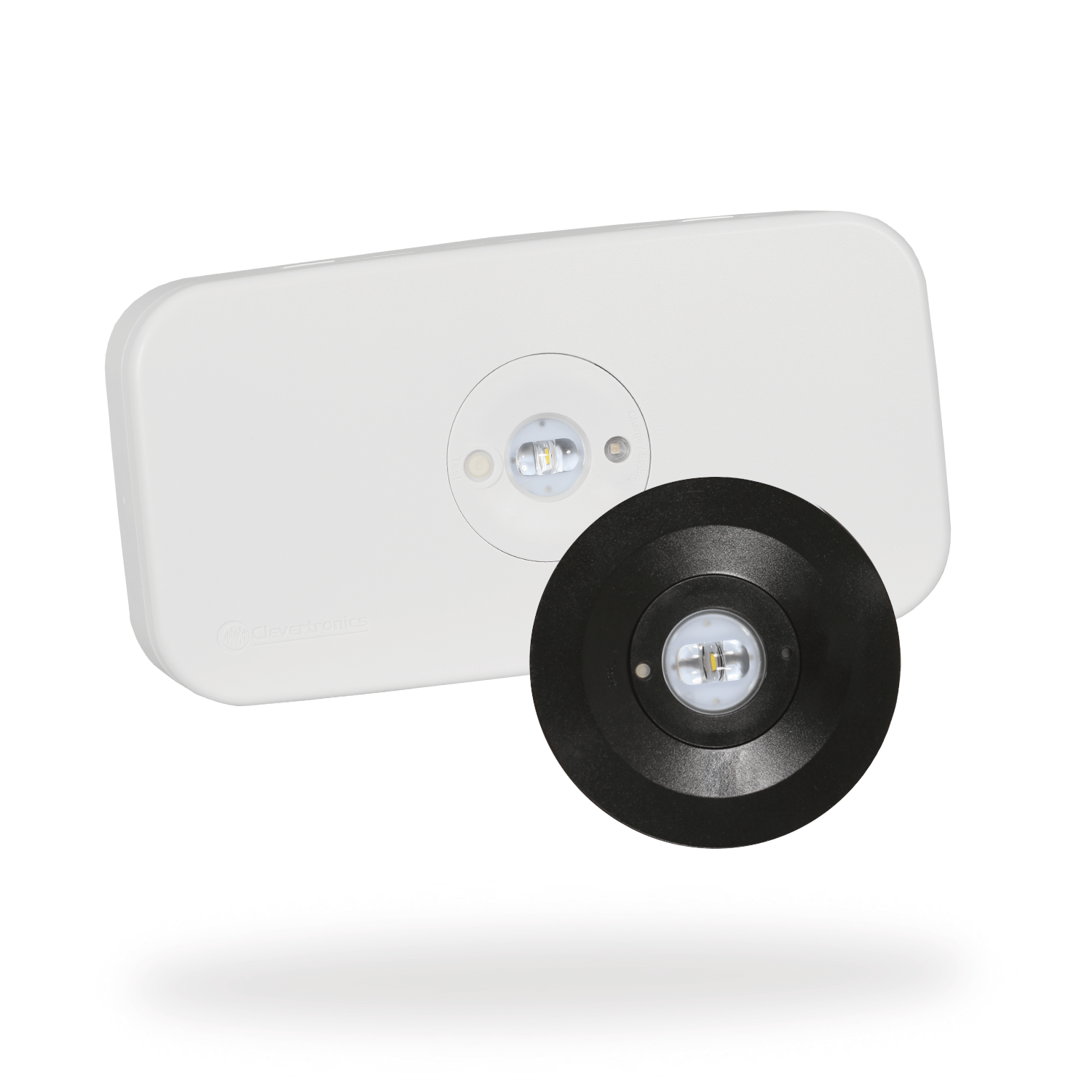

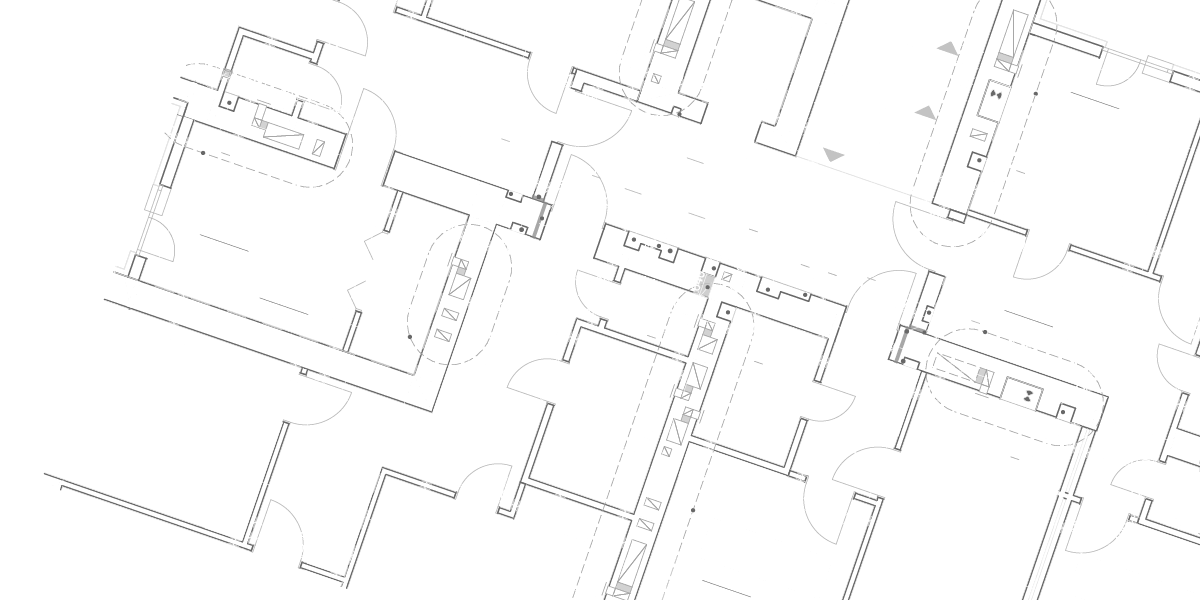

Emergency Lights

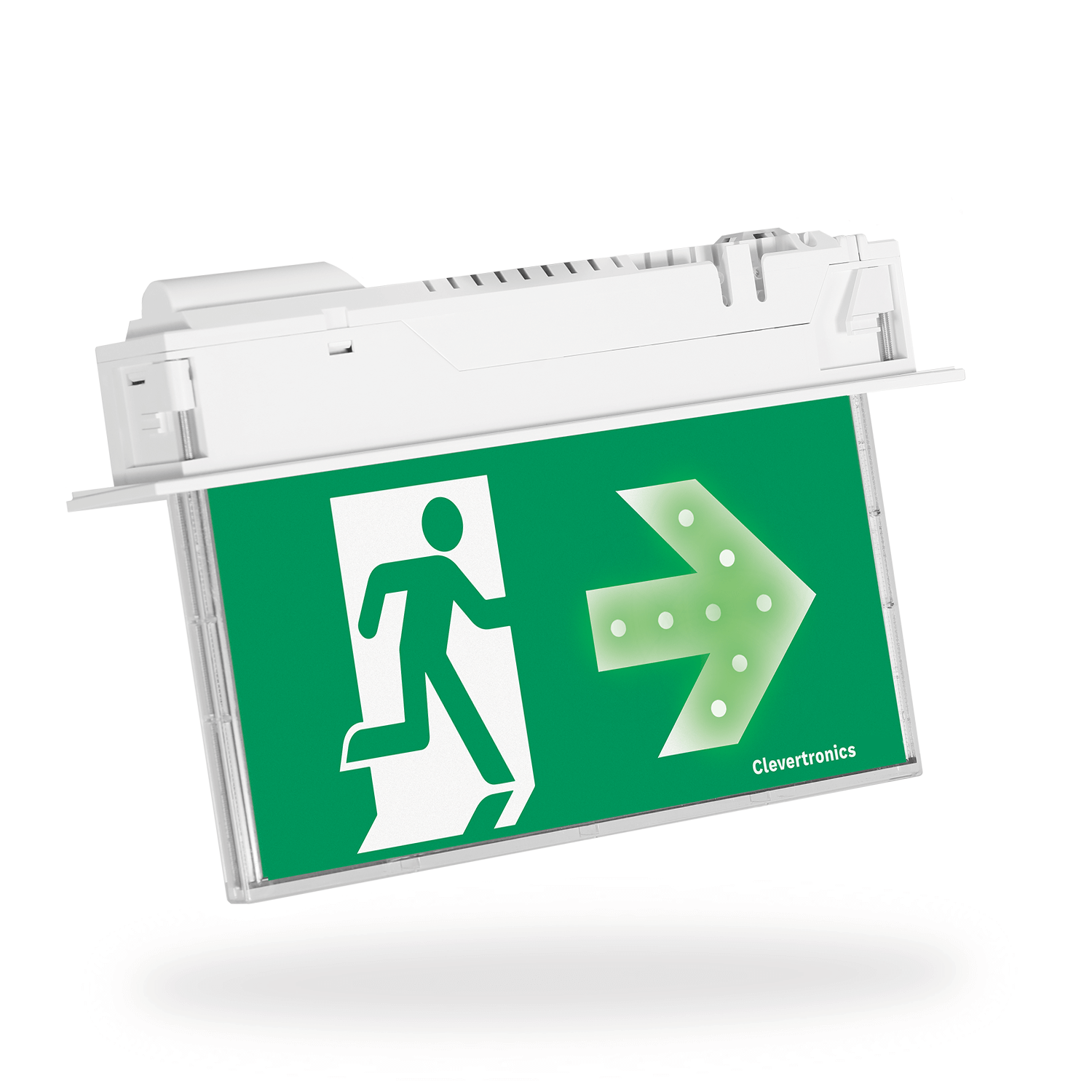

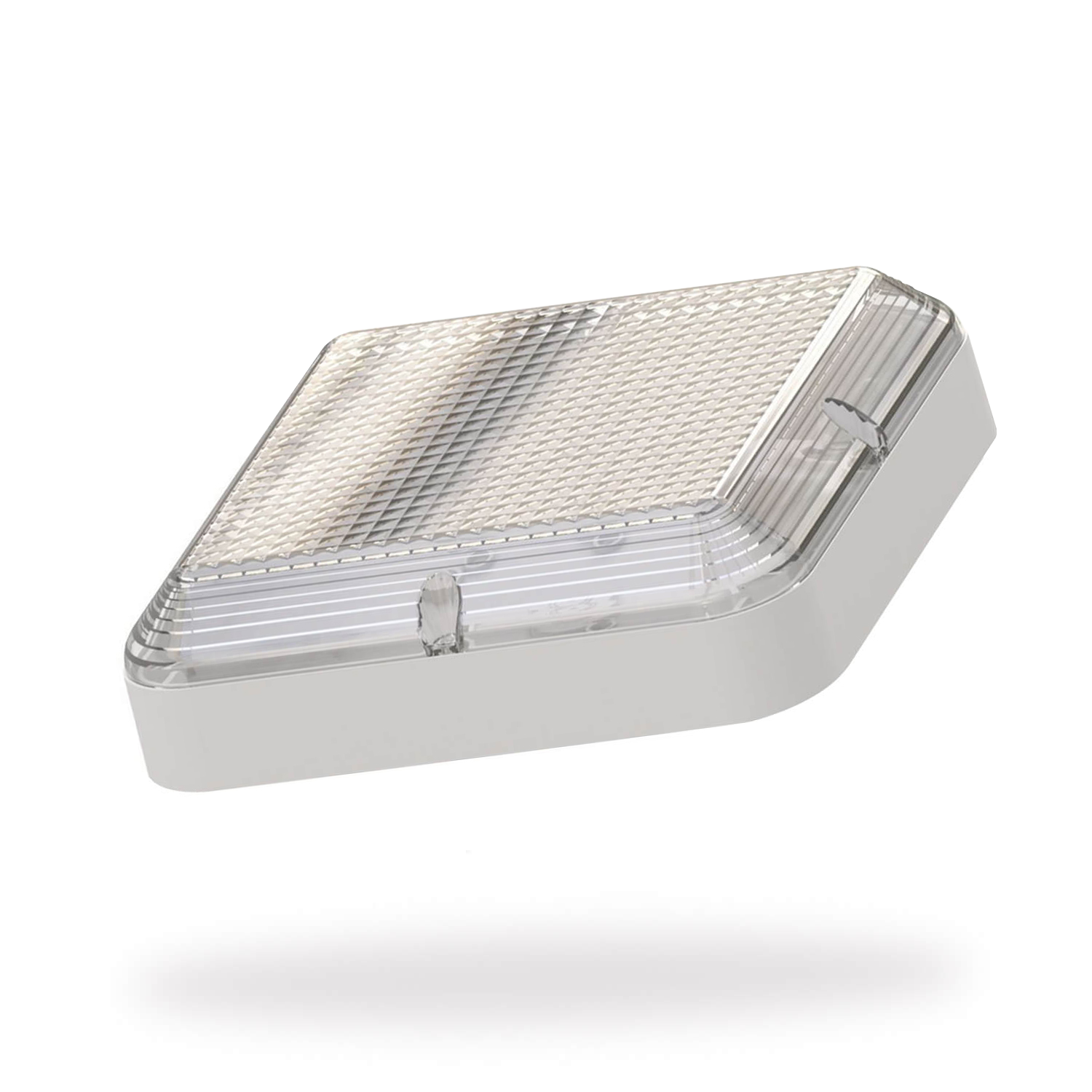

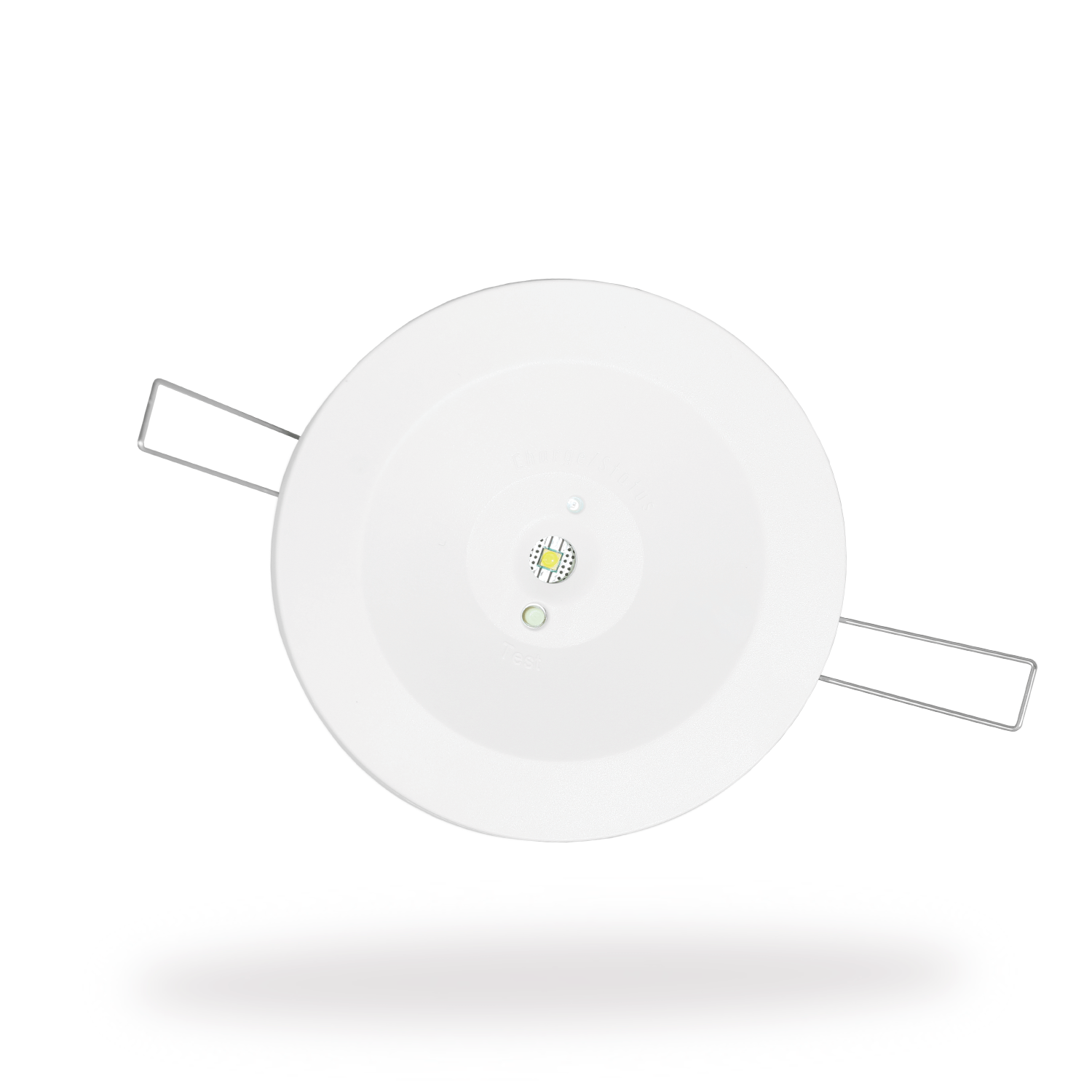

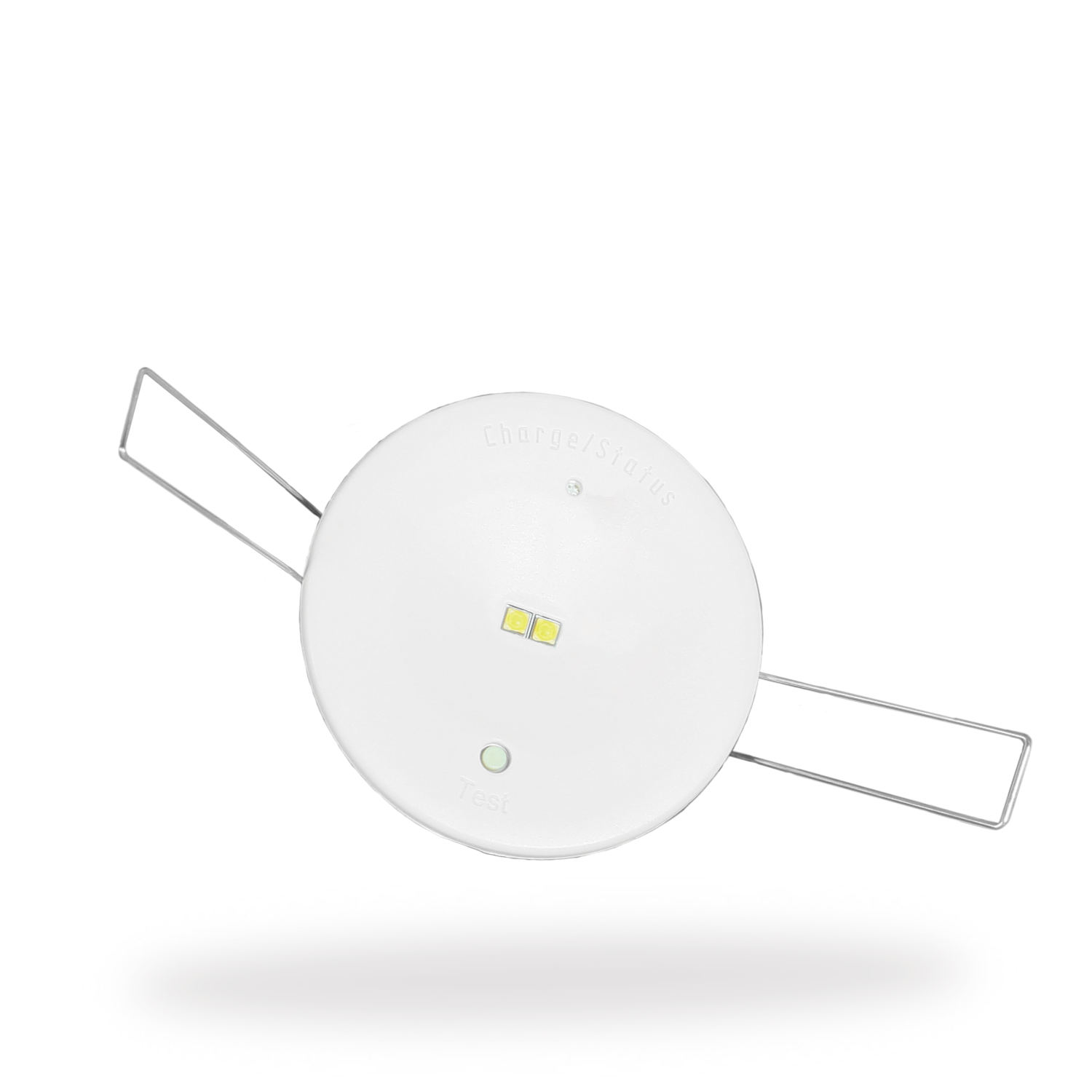

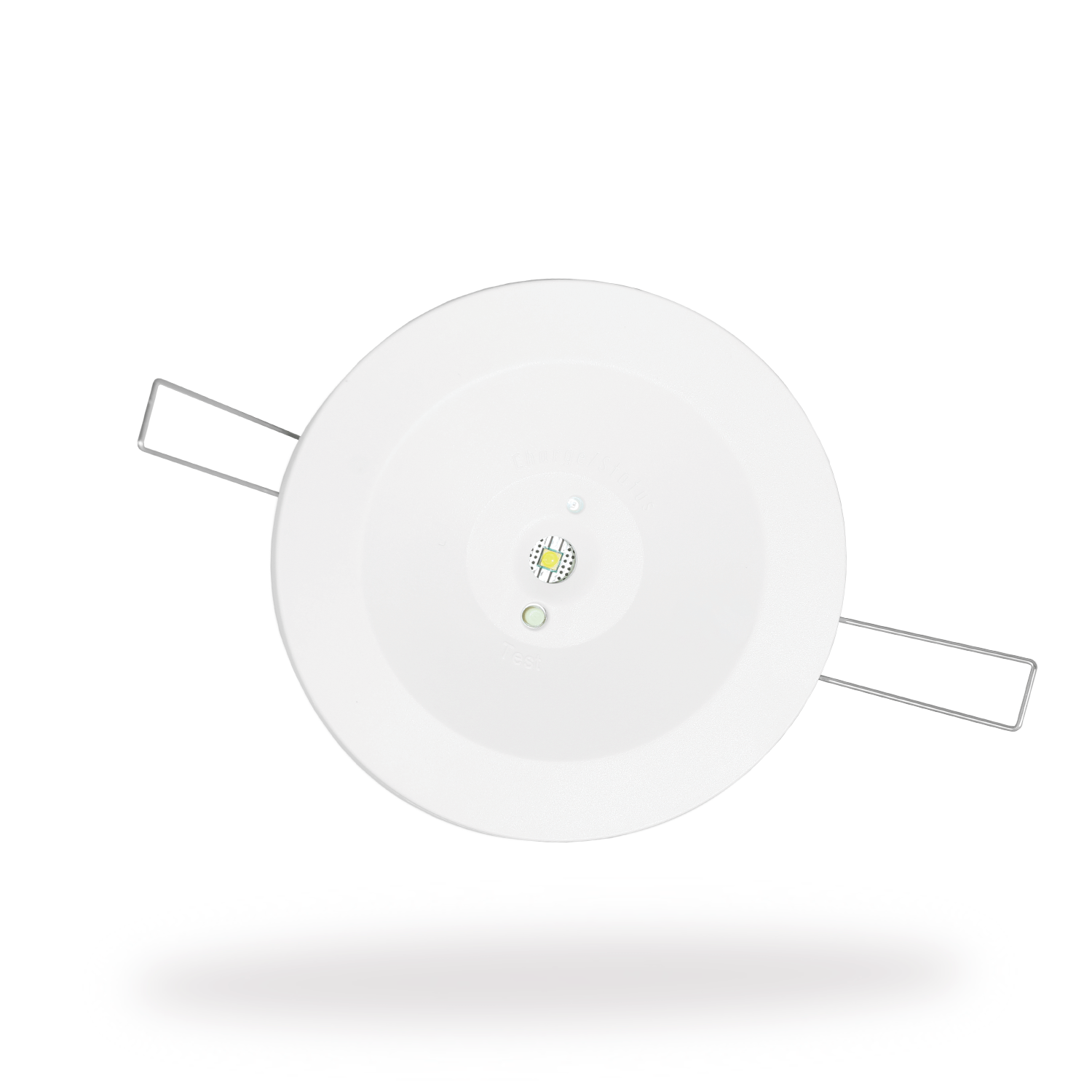

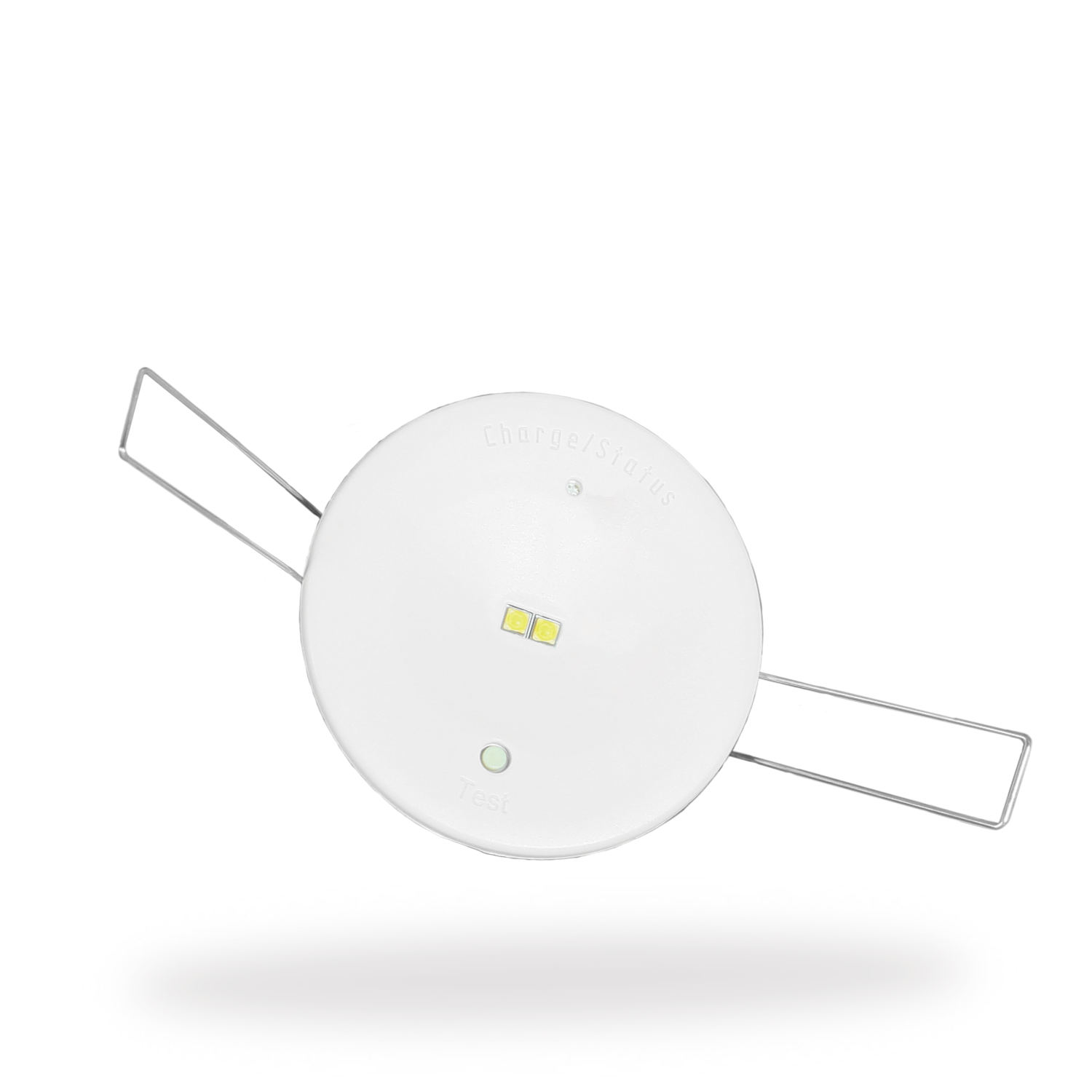

Lifelight Recessed

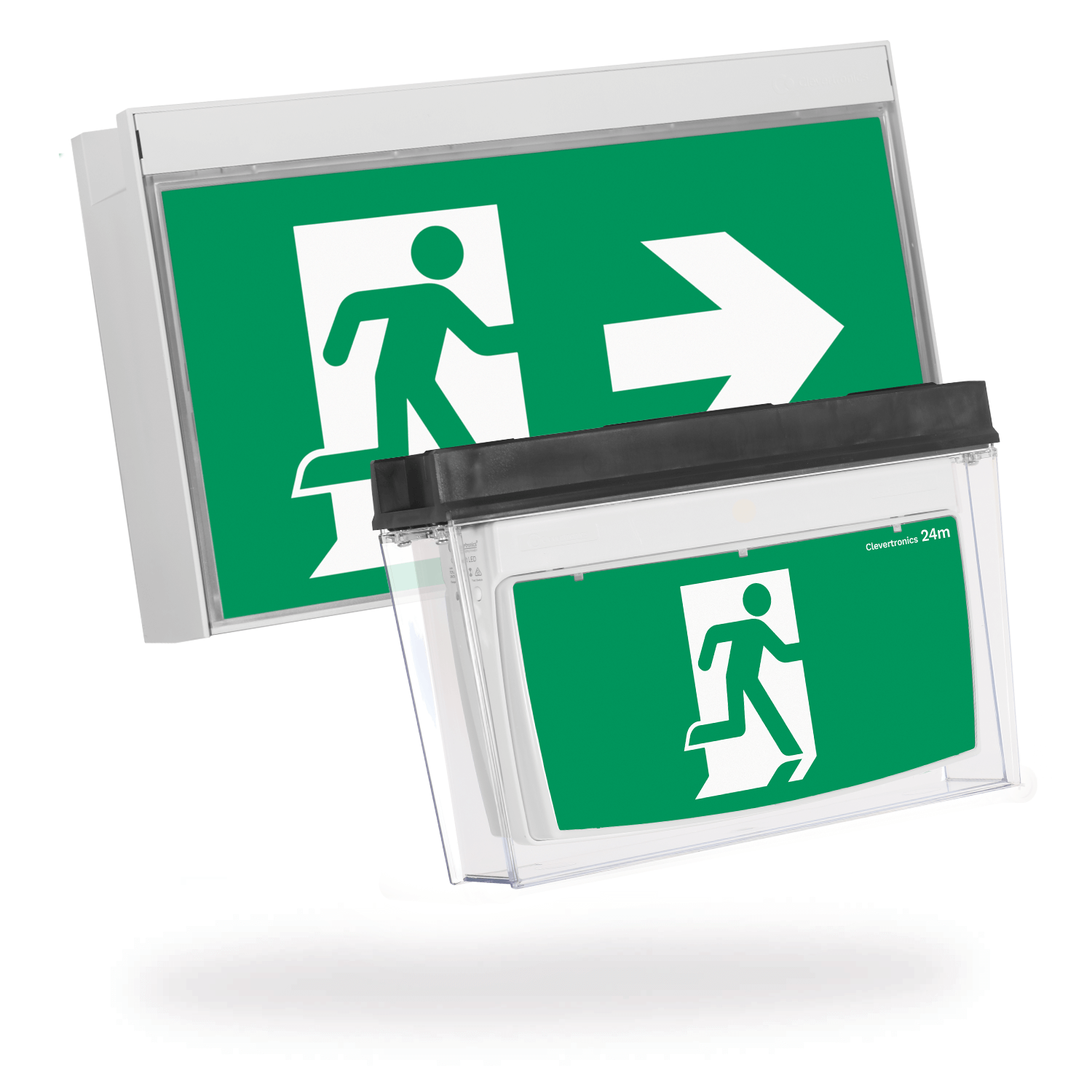

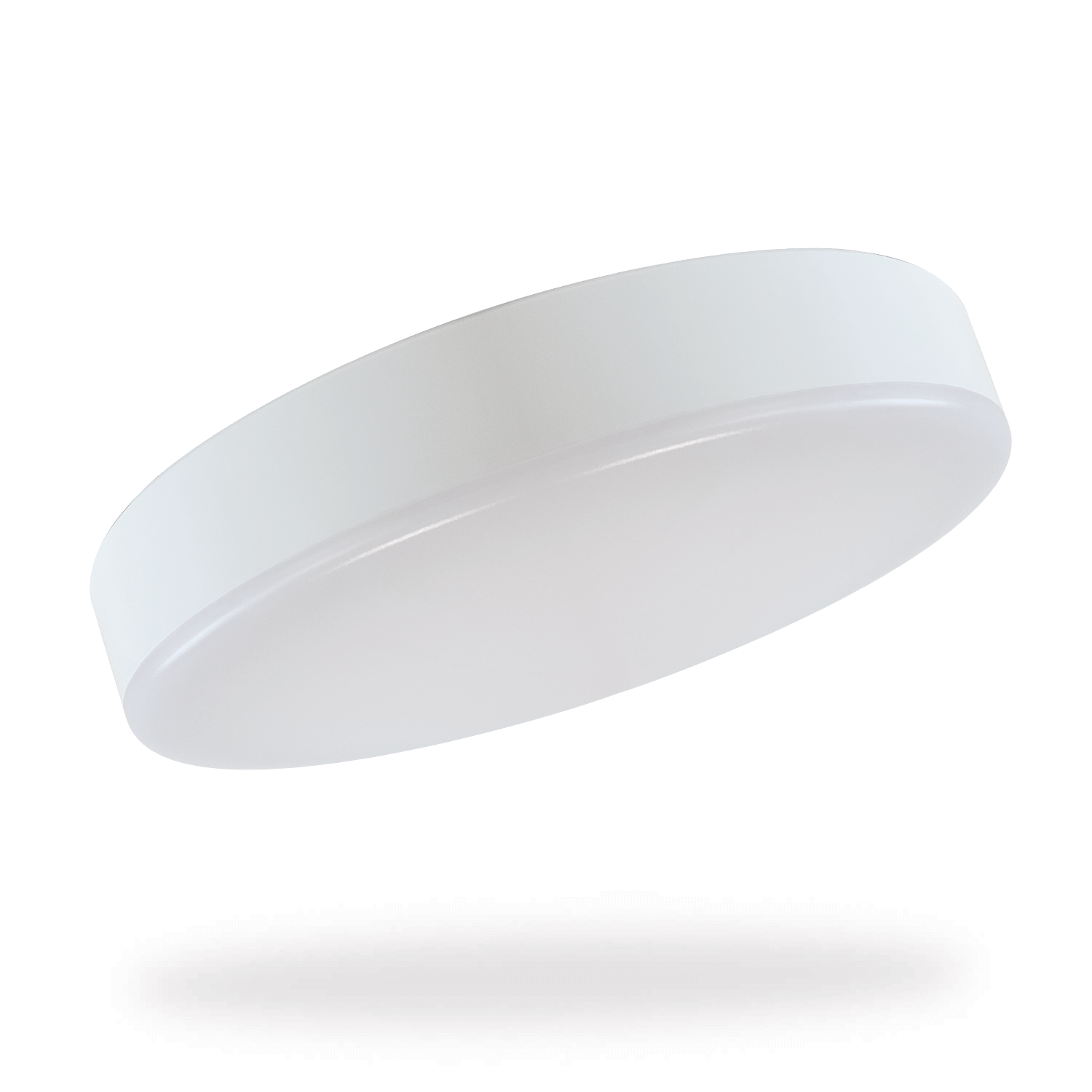

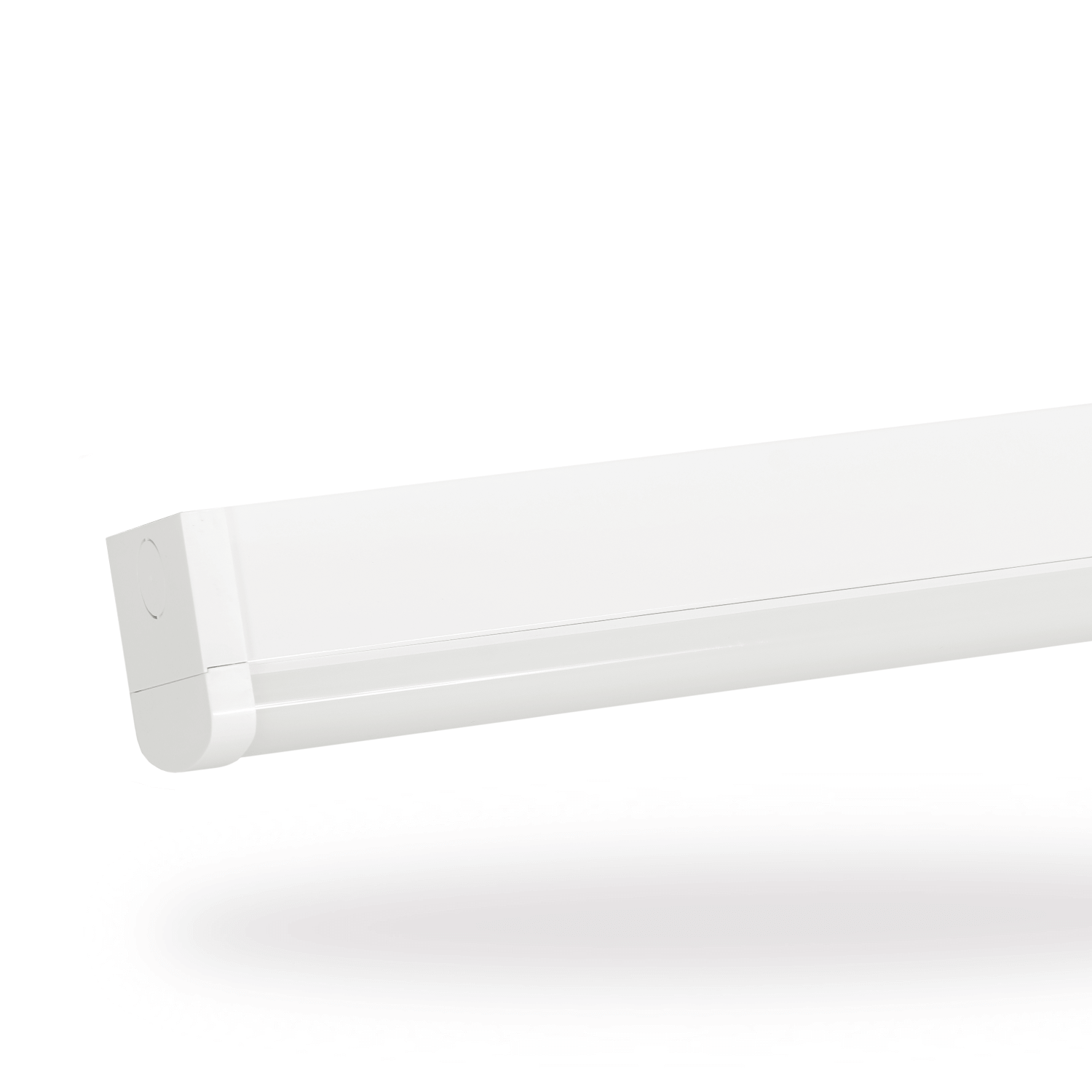

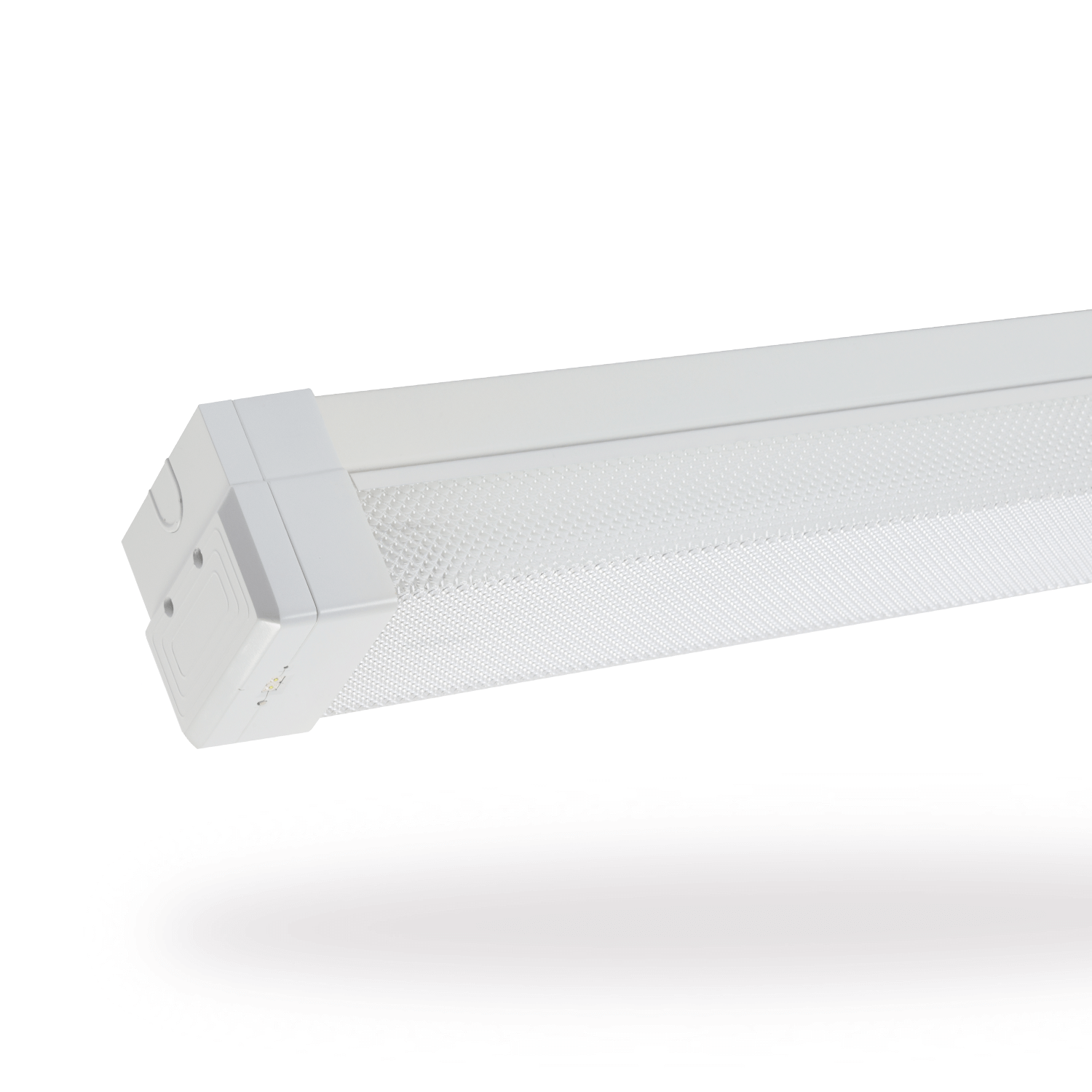

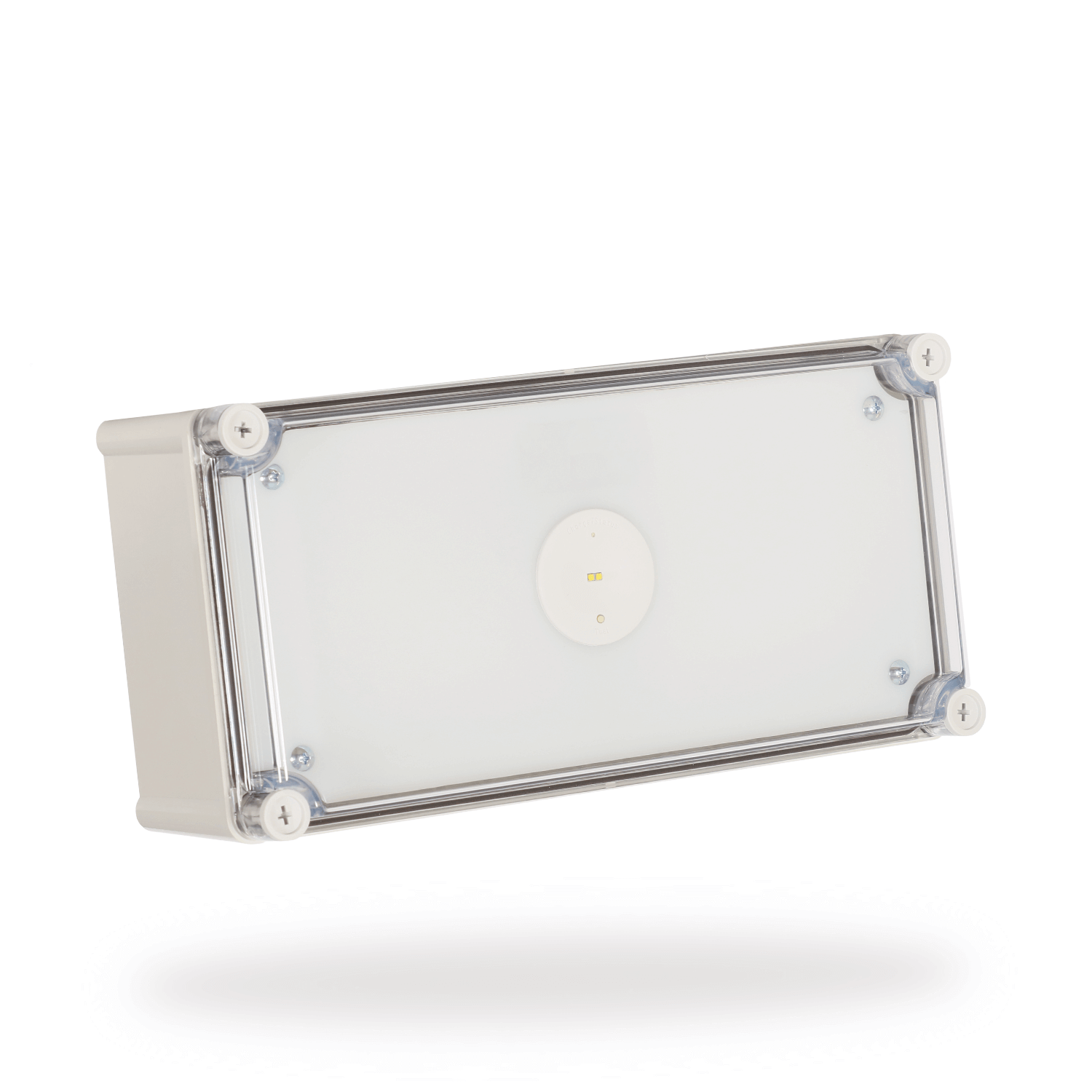

Lifelight Surface Mount

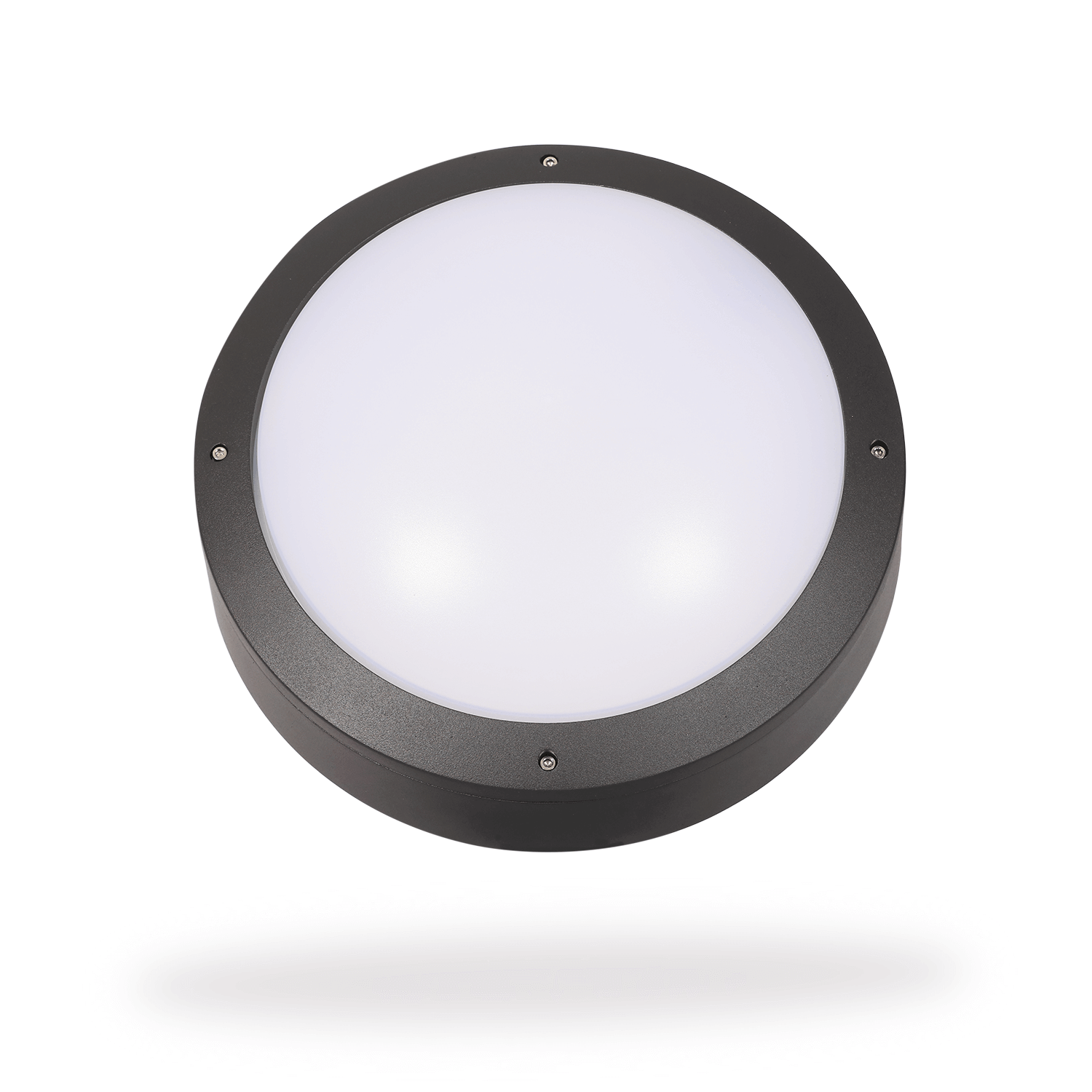

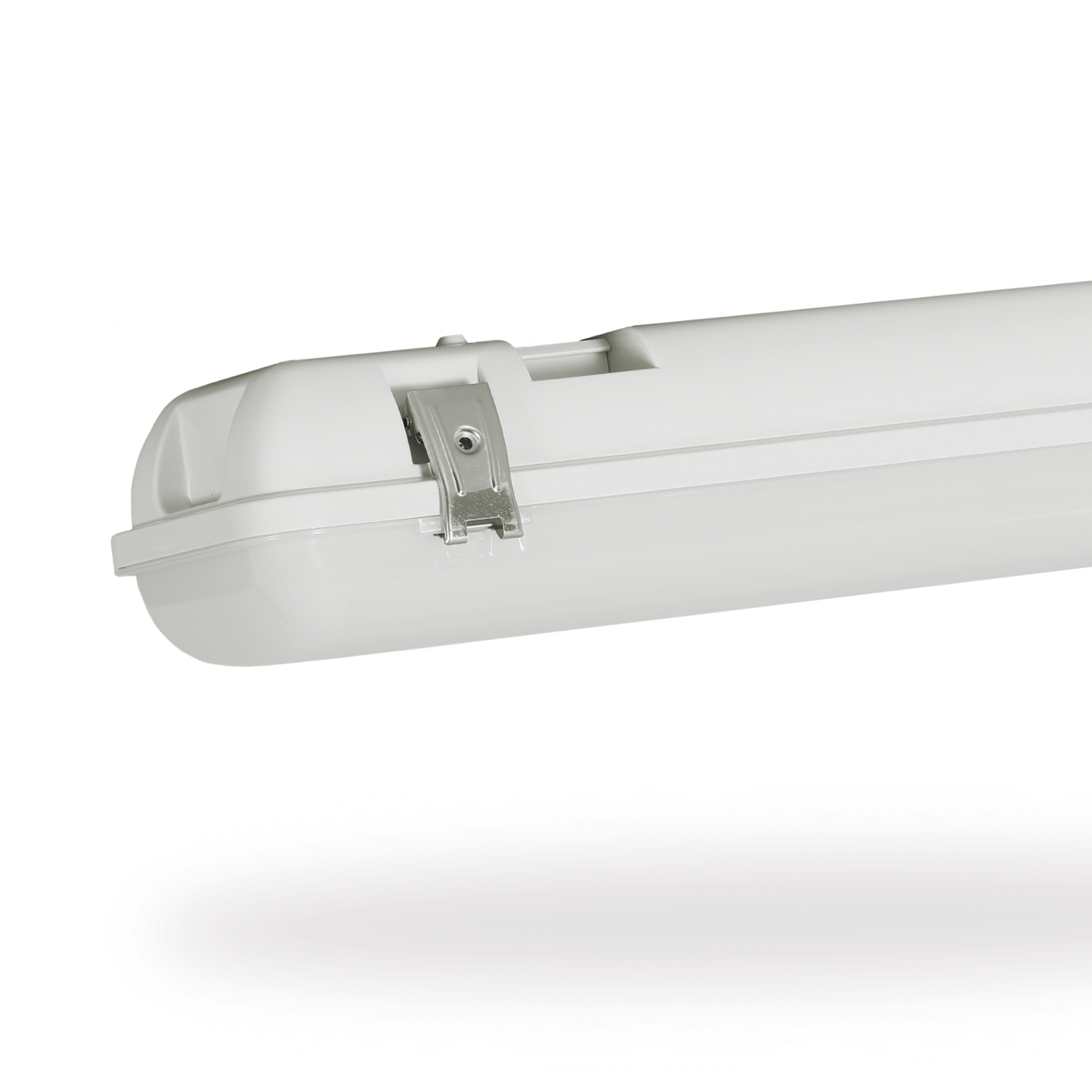

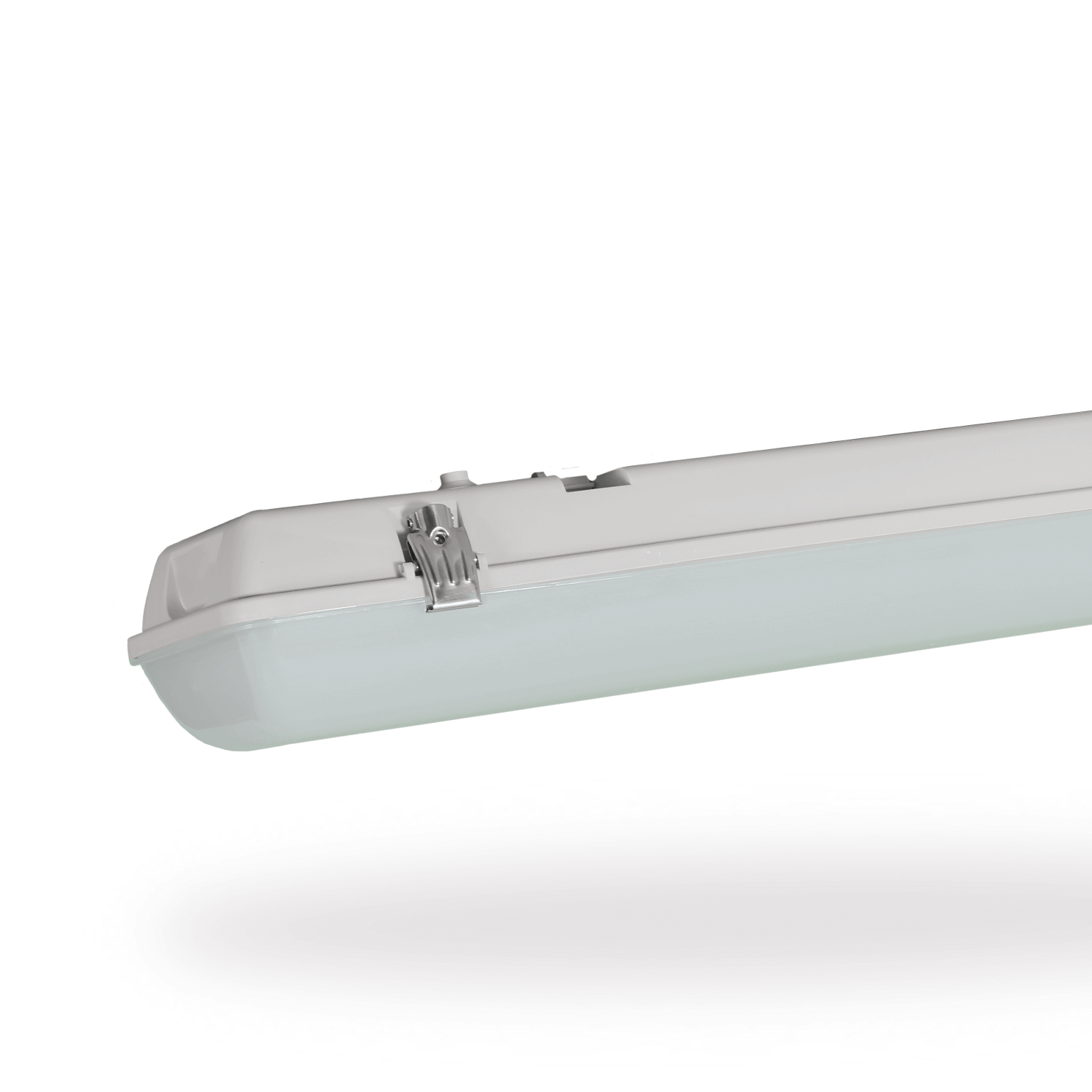

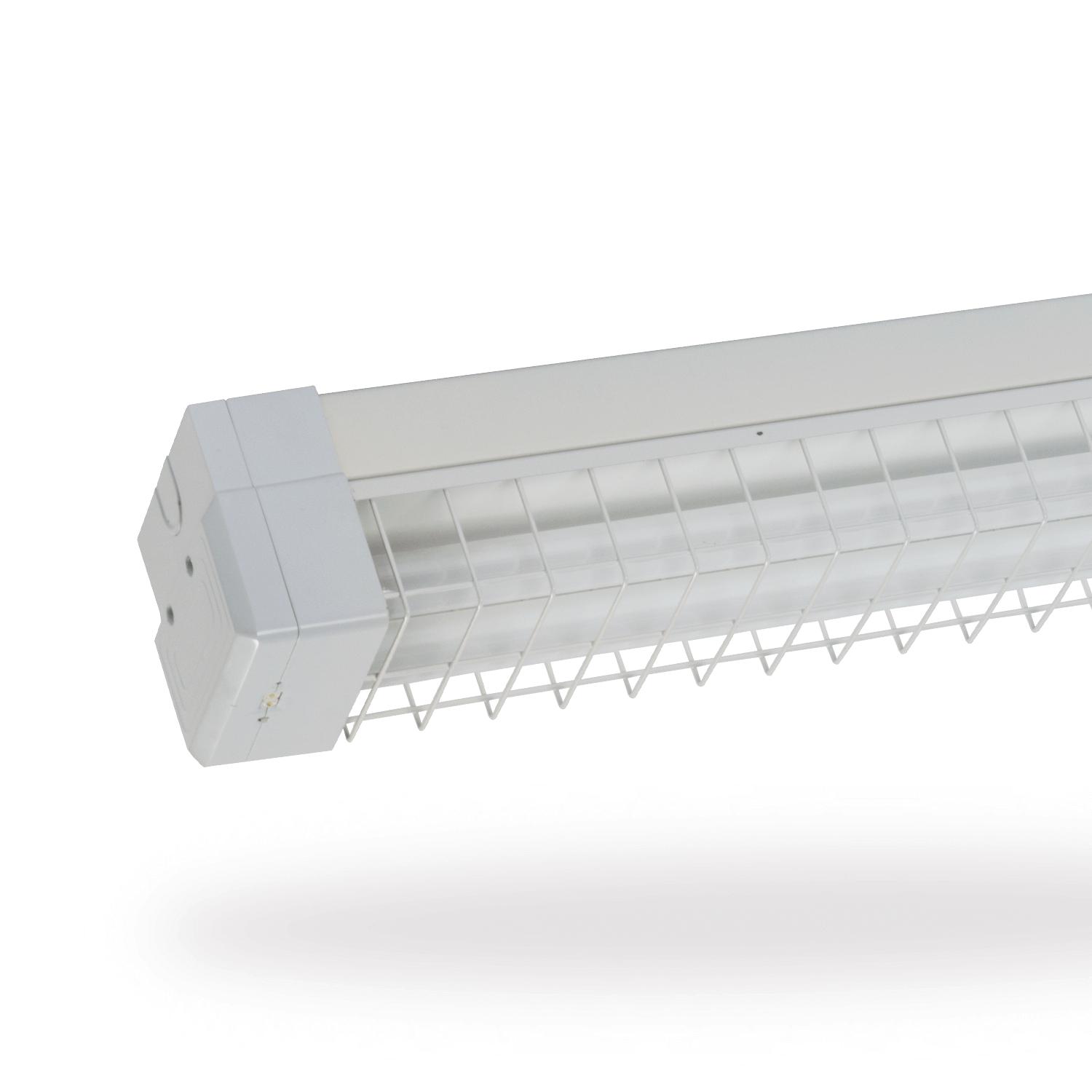

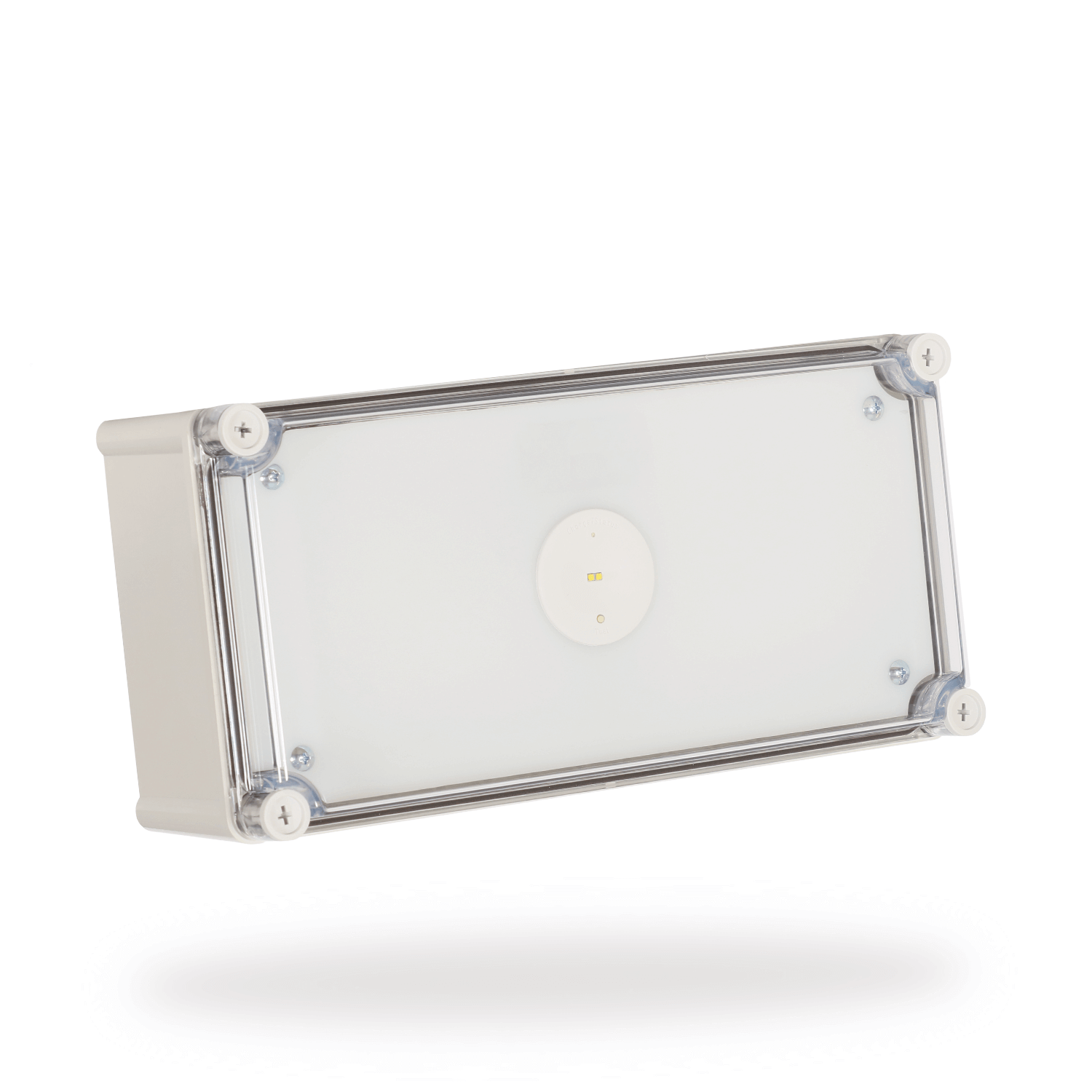

Lifelight Weatherproof Surface Mount

Lifelight PRO Recessed

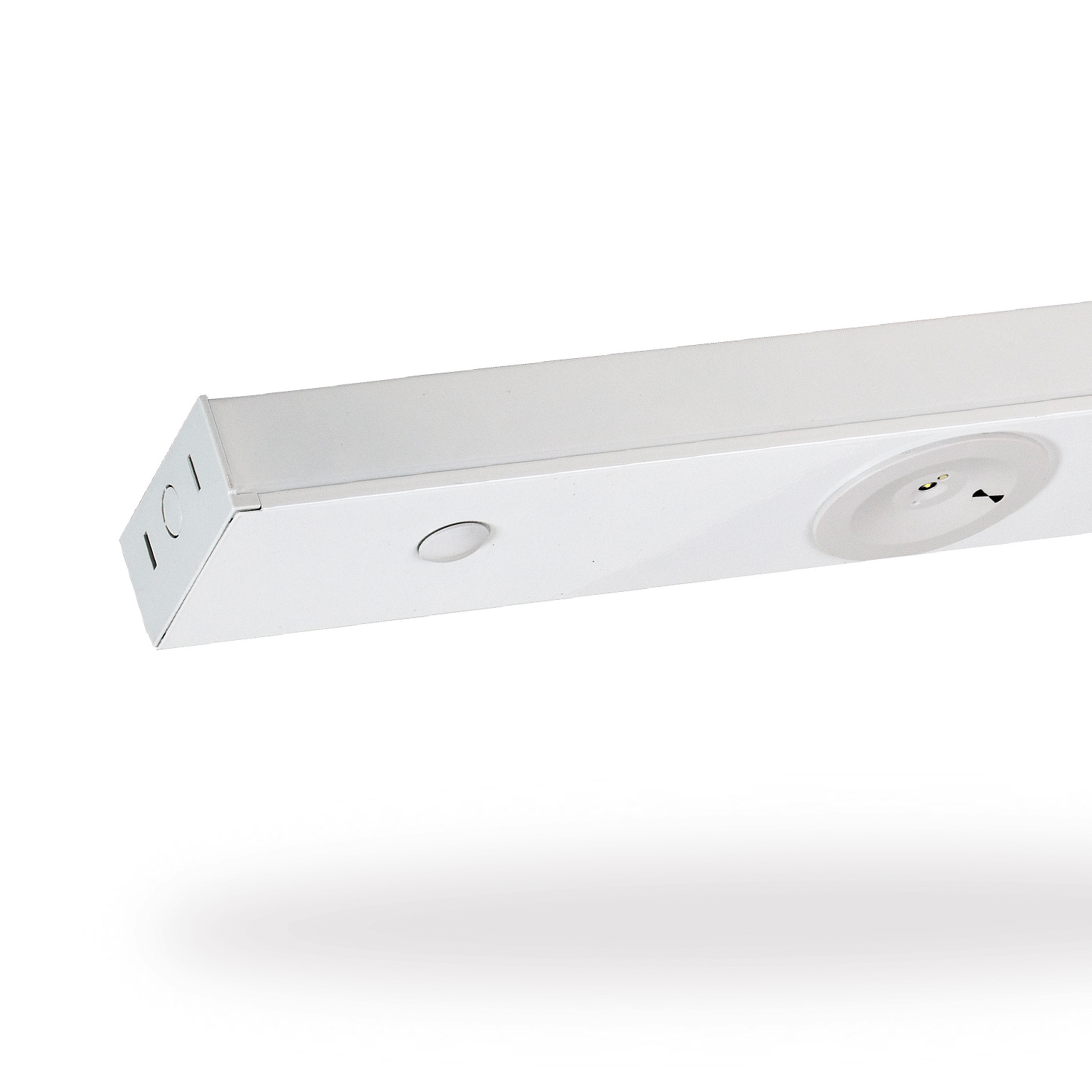

Lifelight PRO Surface Mount

Lifelight PRO Cylinder Surface Mount

Lifelight PRO Weatherproof Surface Mount

Lifelight PRO Low Temperature

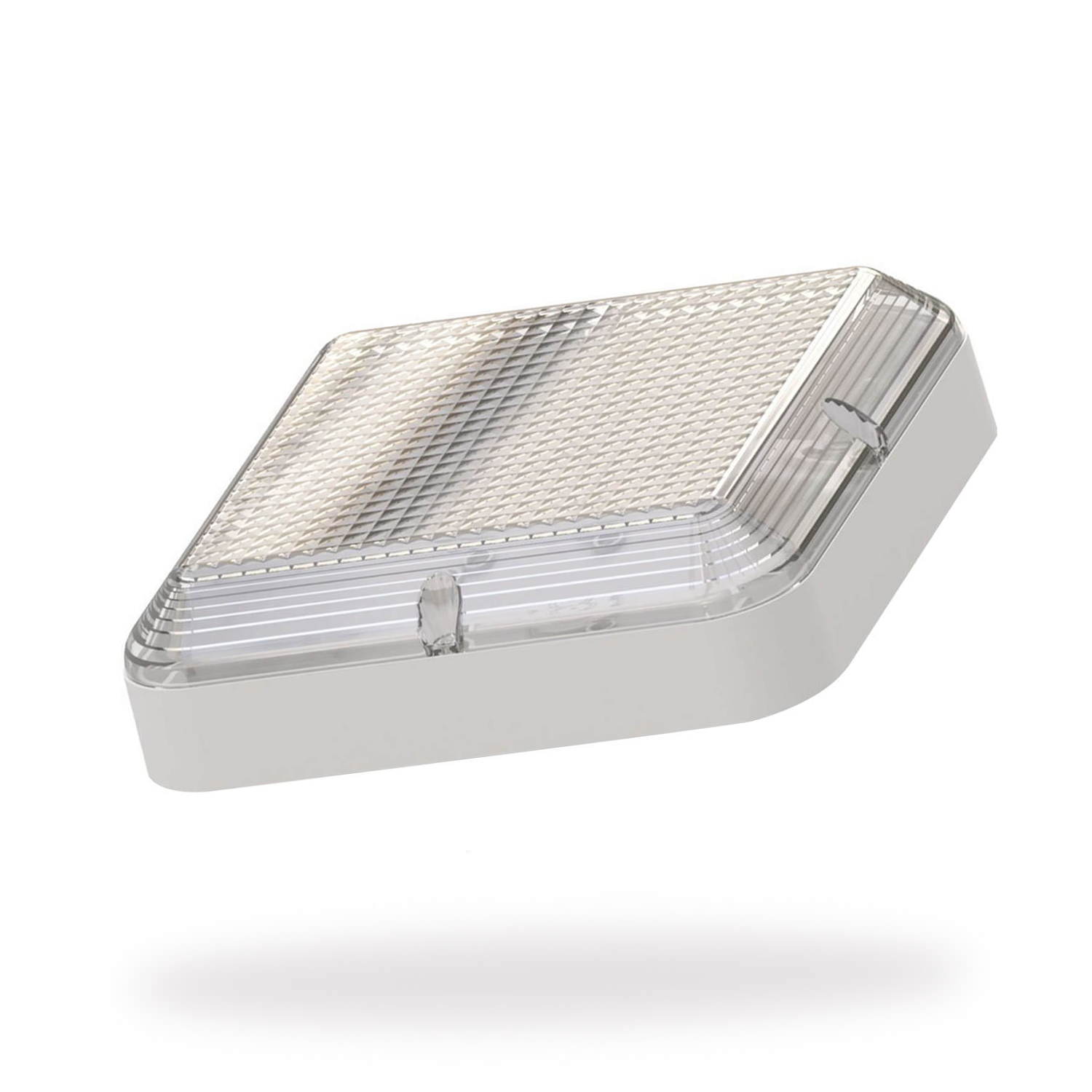

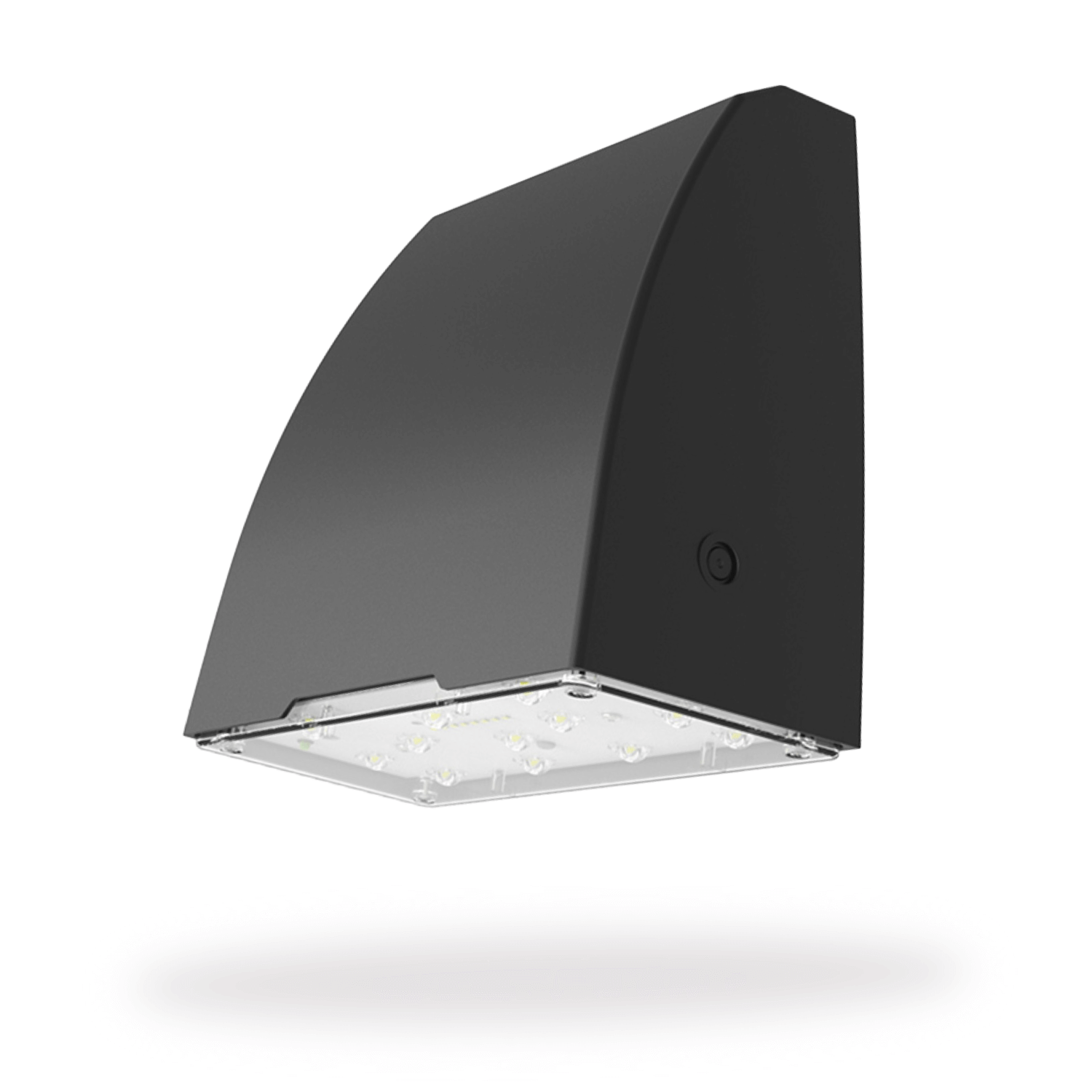

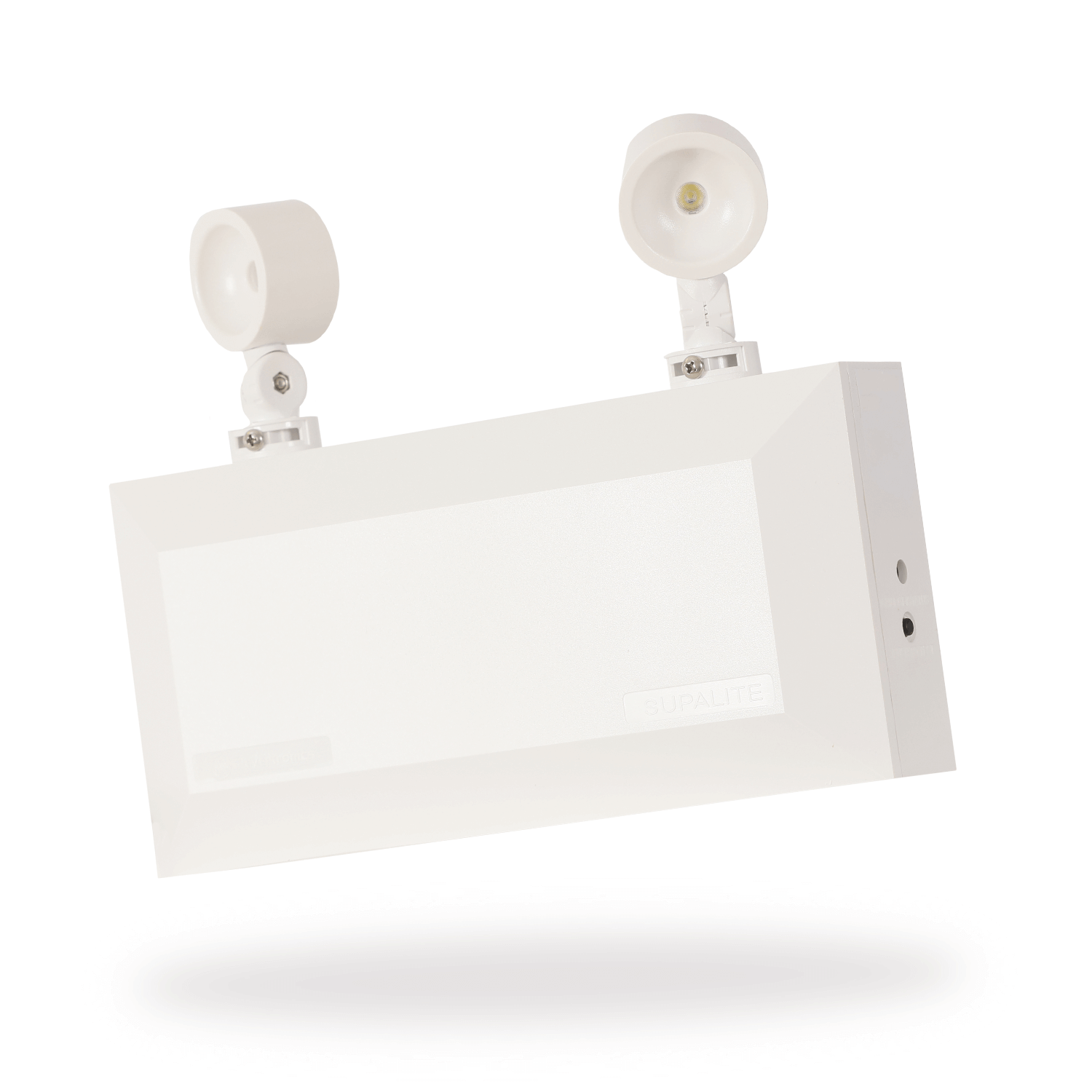

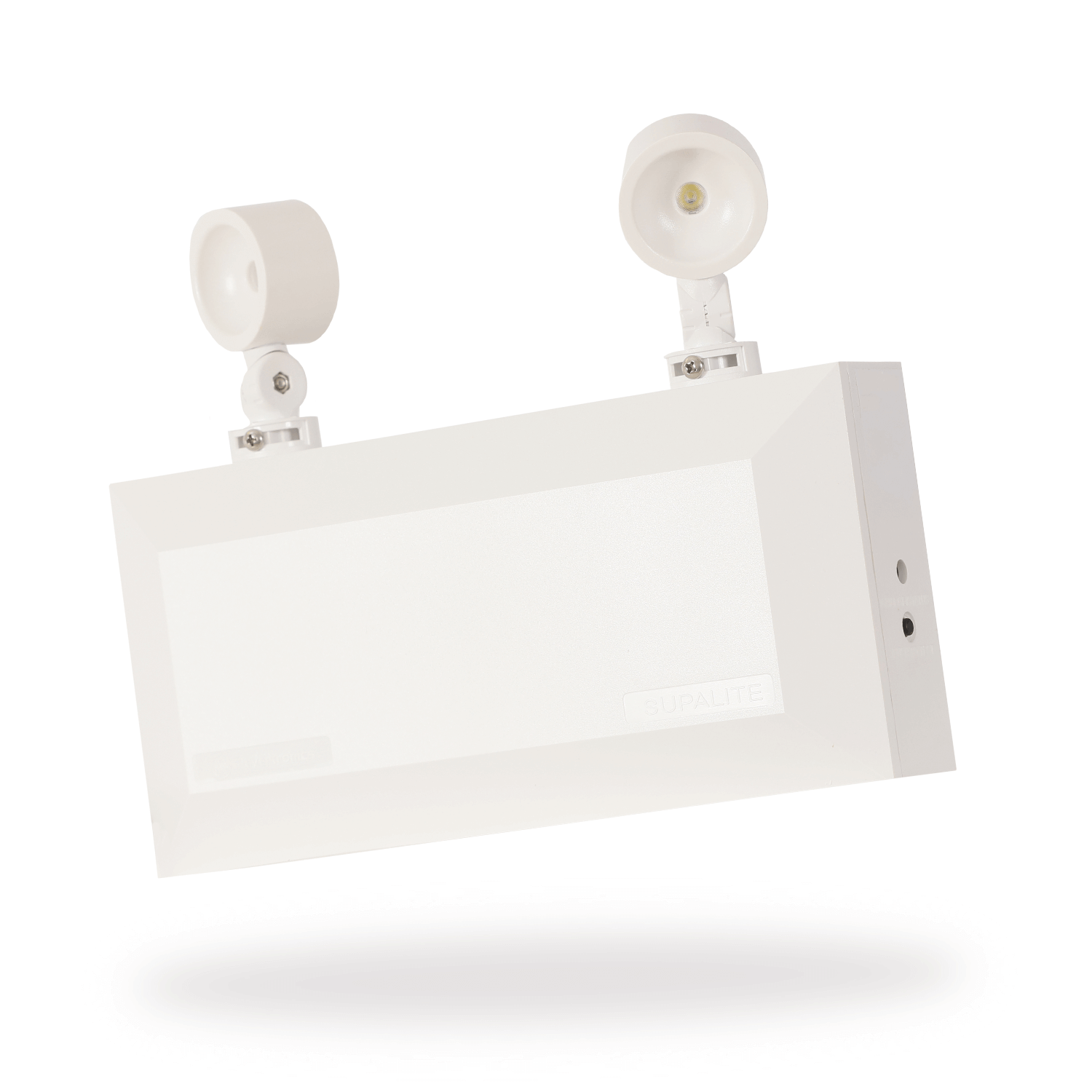

Supalite Flood

Nifty Lifelight Recessed

Nifty Lifelight Surface Mount

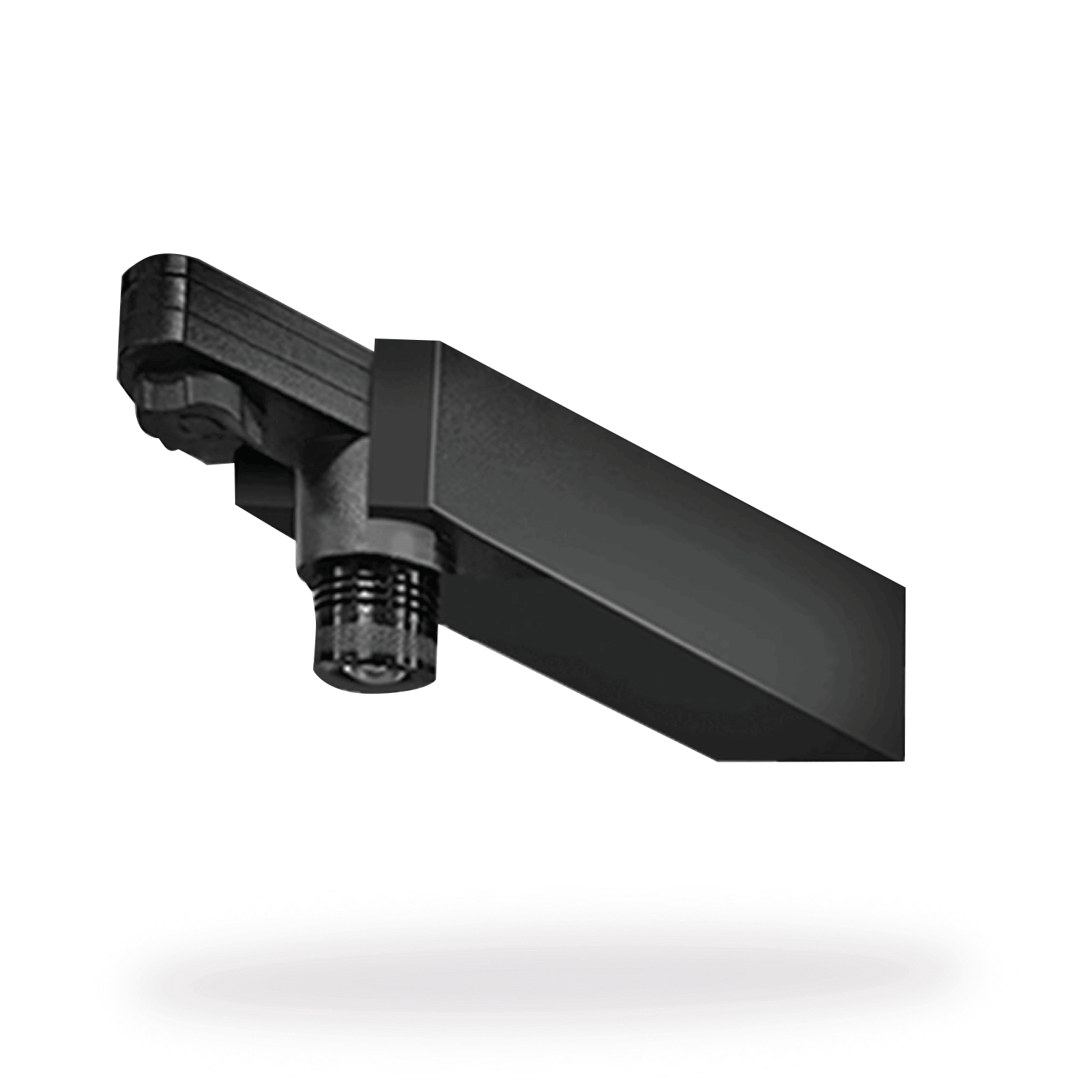

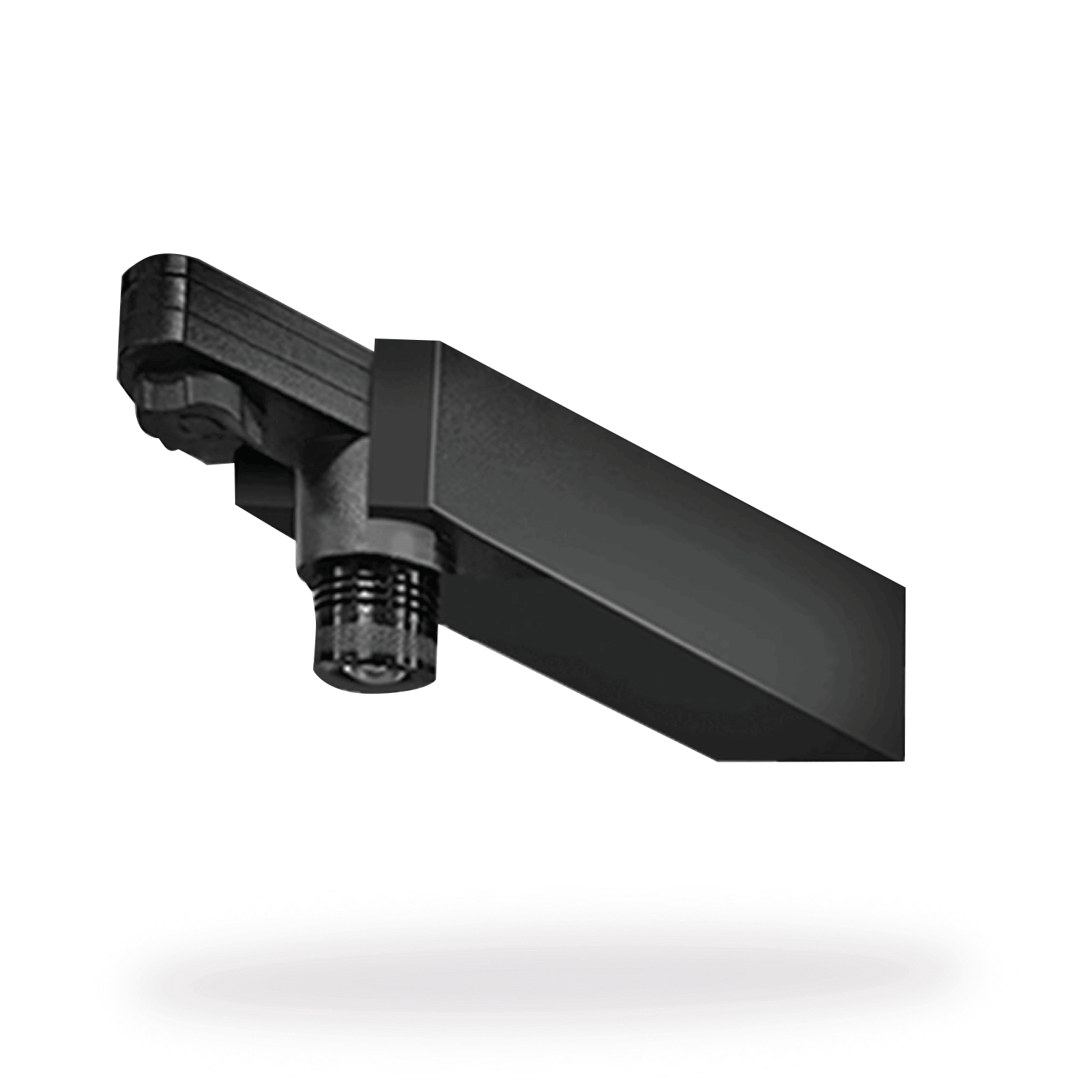

Lifelight Track Mount

Trusted by some of the world's largest brands