Nanophosphate® Lithium-Ion Battery Technology

The first and only Nanophosphate® powered product on the market

- Lowest total ownership cost

- 50% longer battery life vs any other lithium product

- 60% maintenance savings vs any other lithium product

- Standard Clevertest Plus

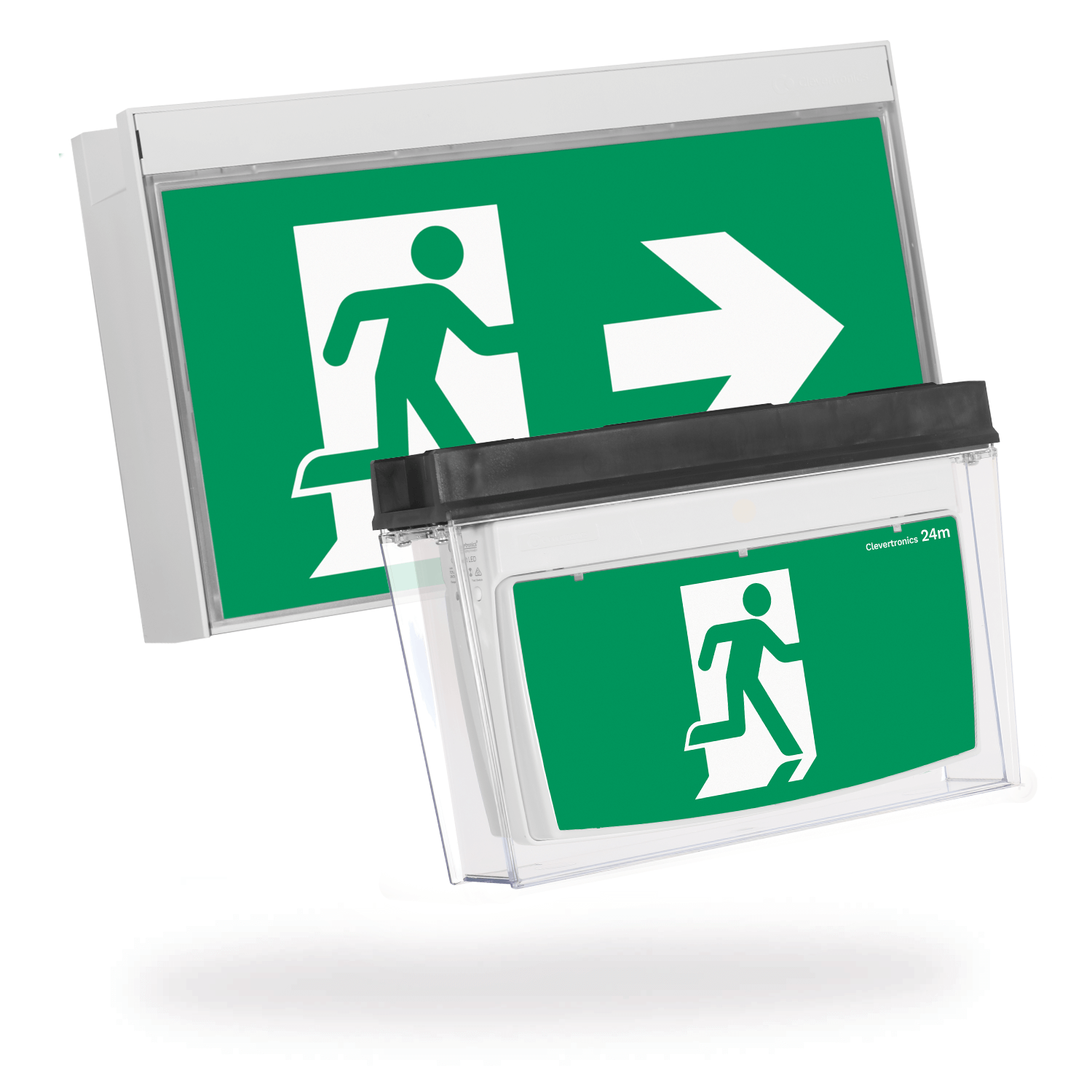

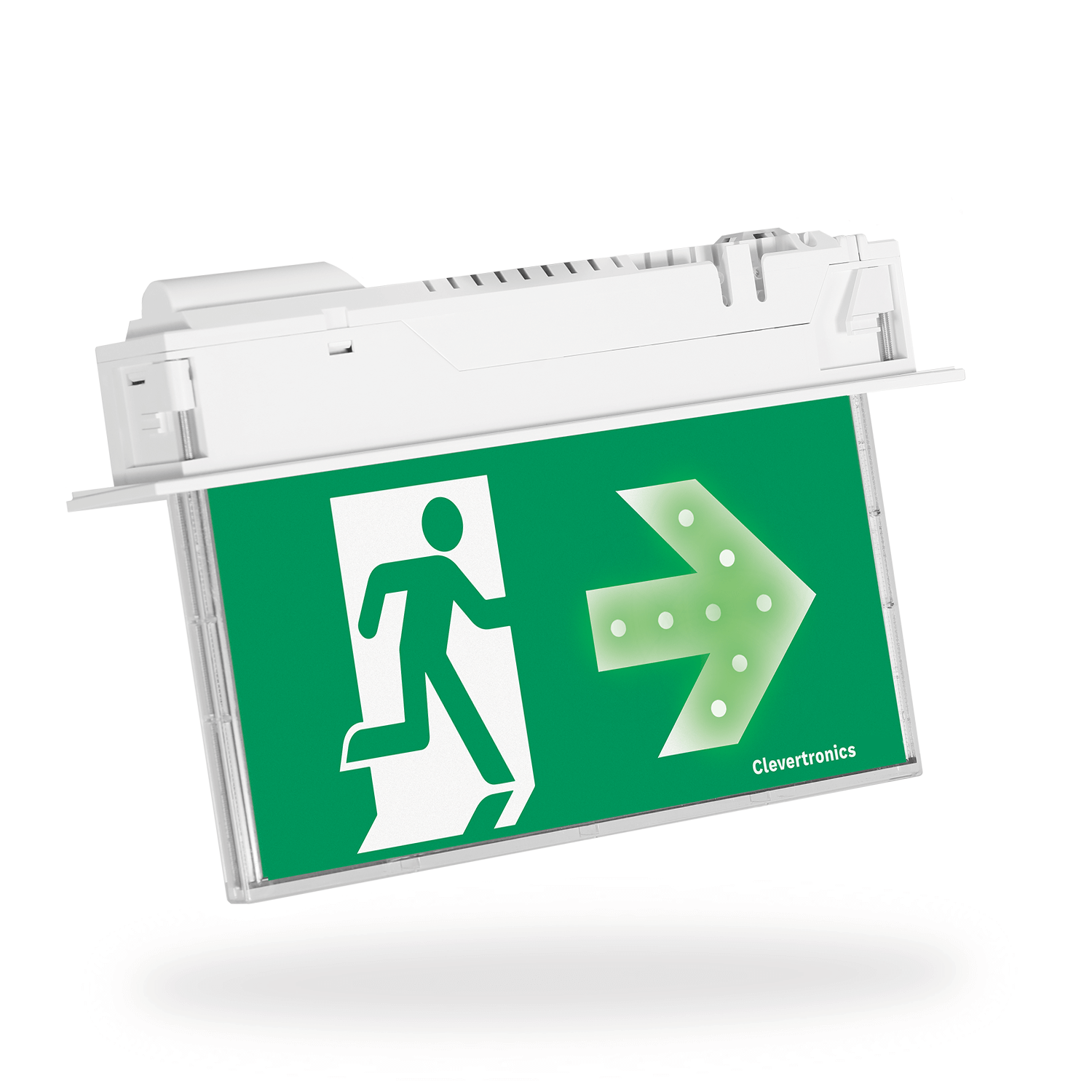

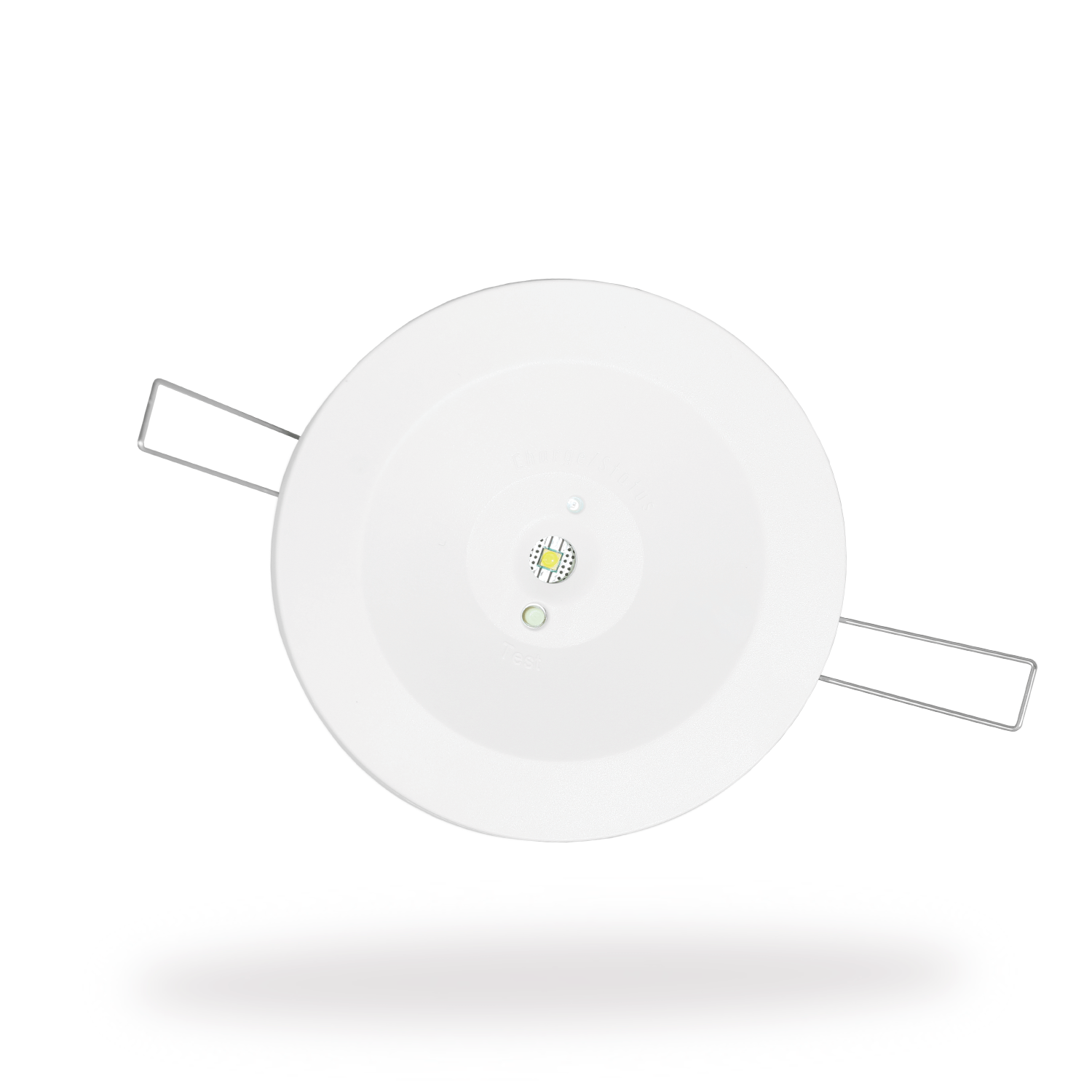

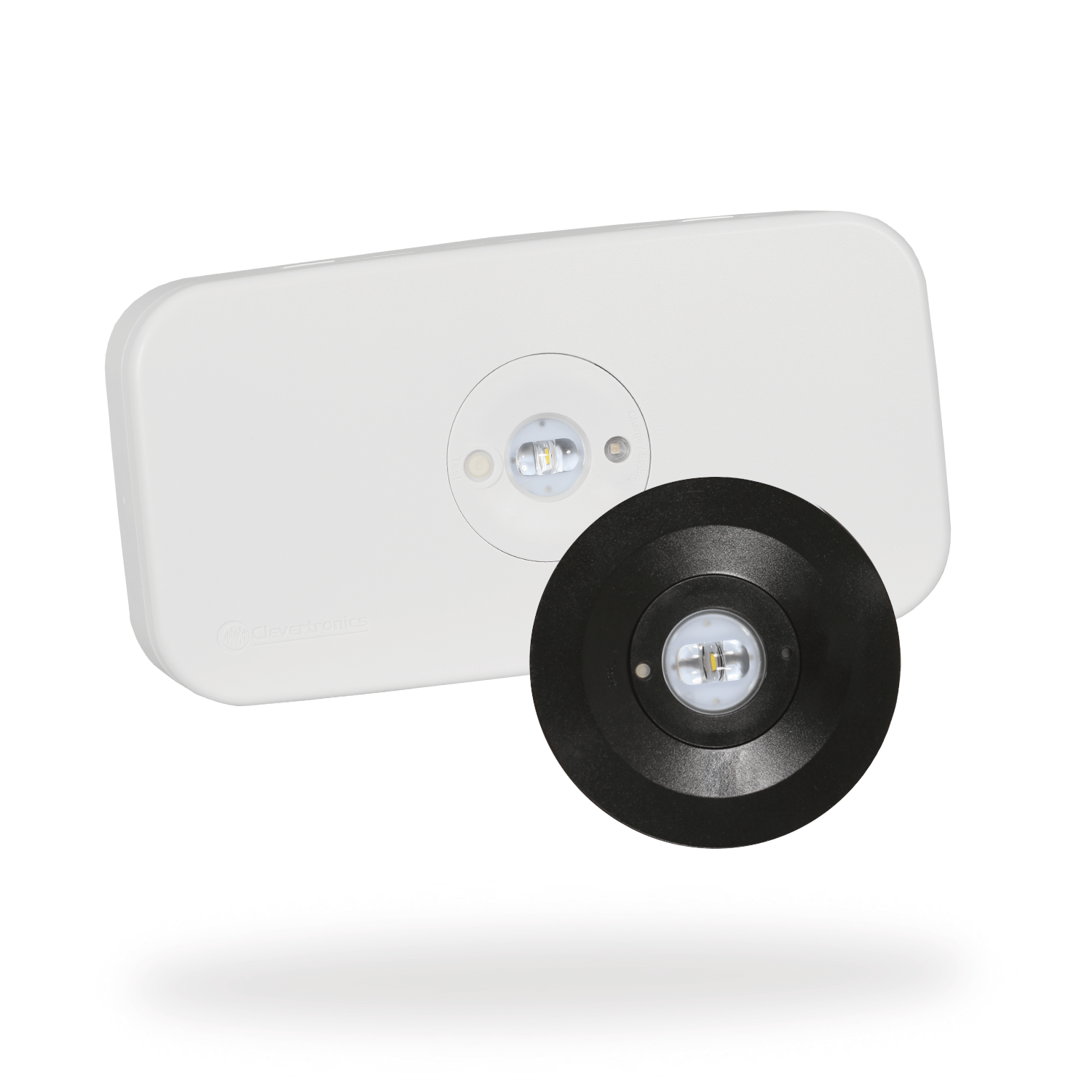

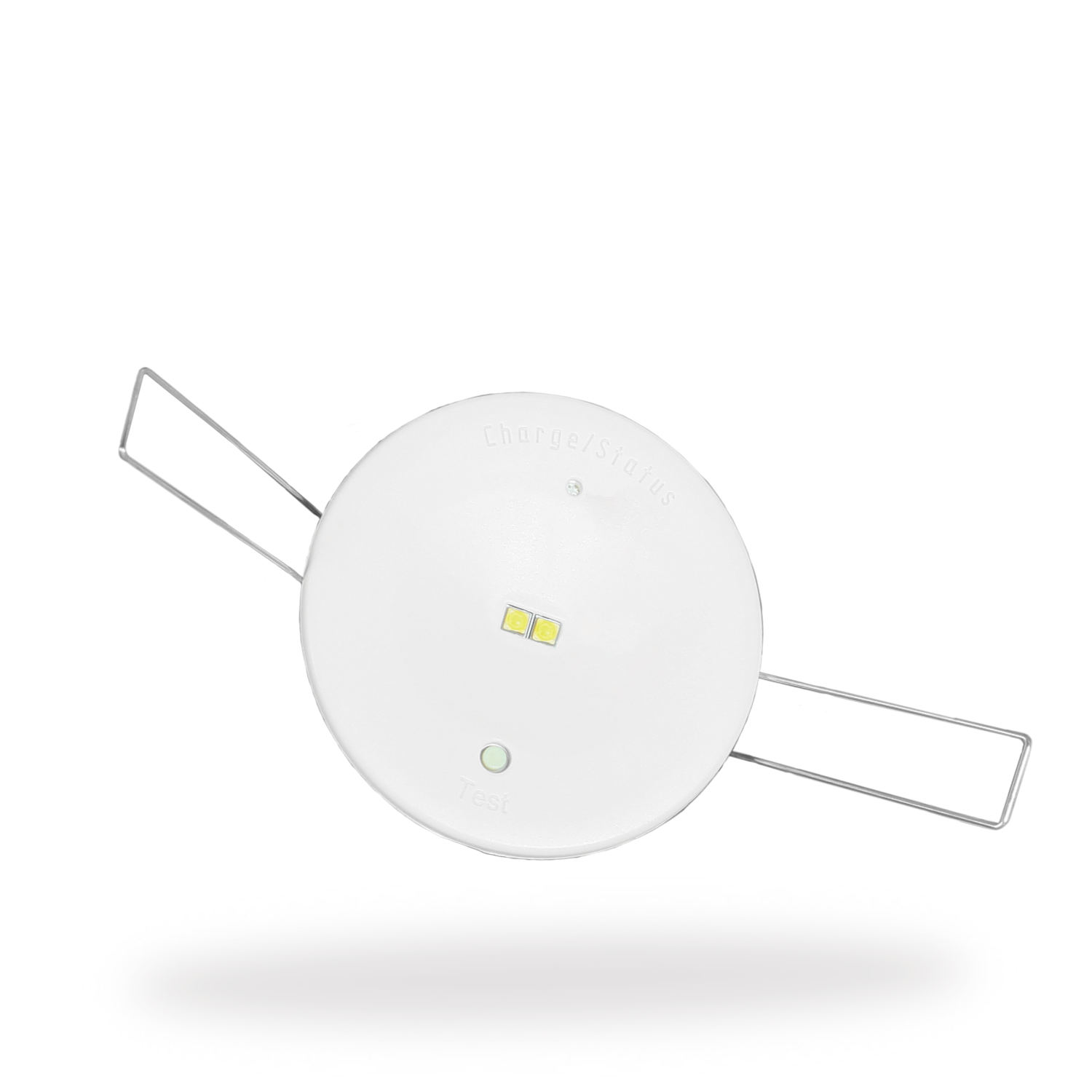

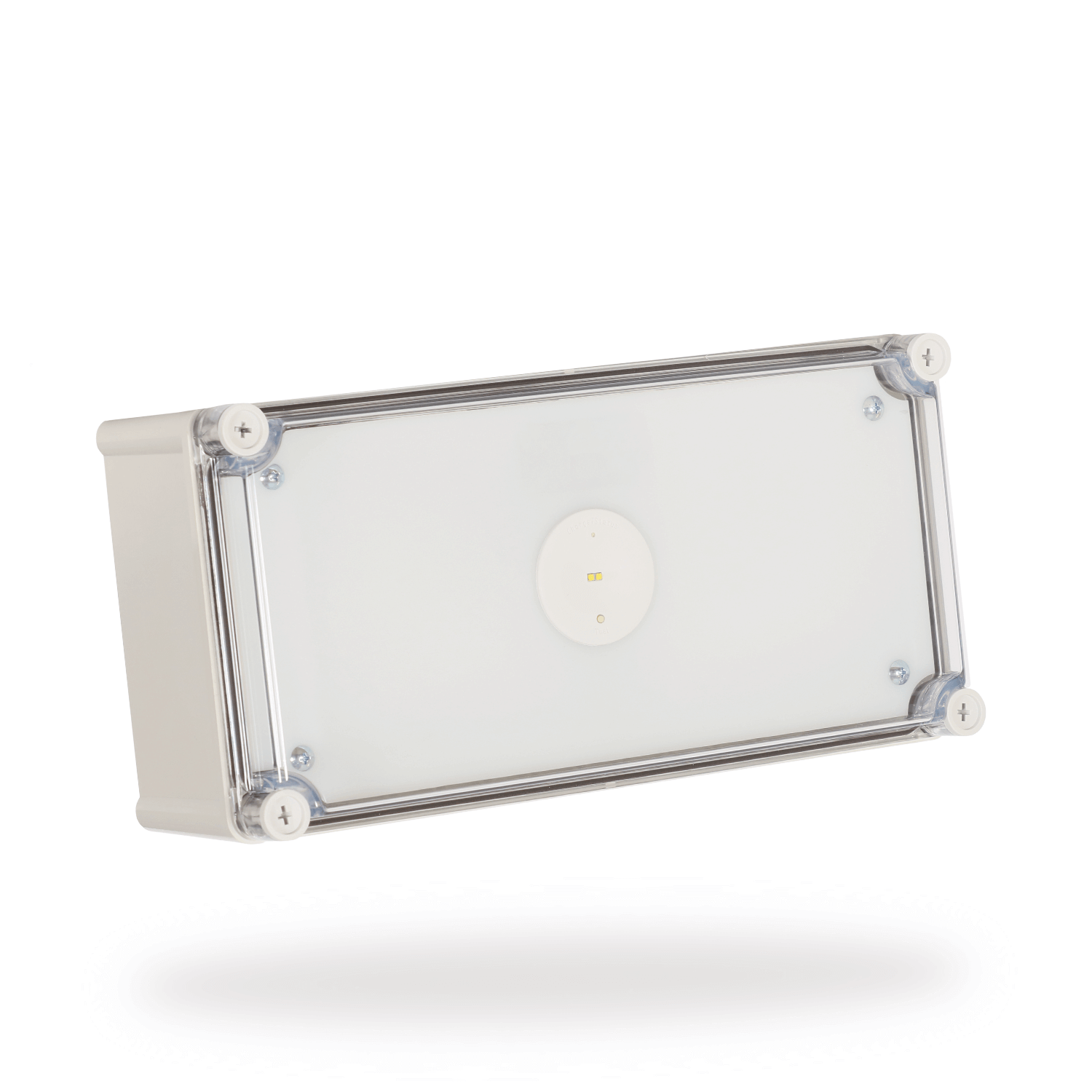

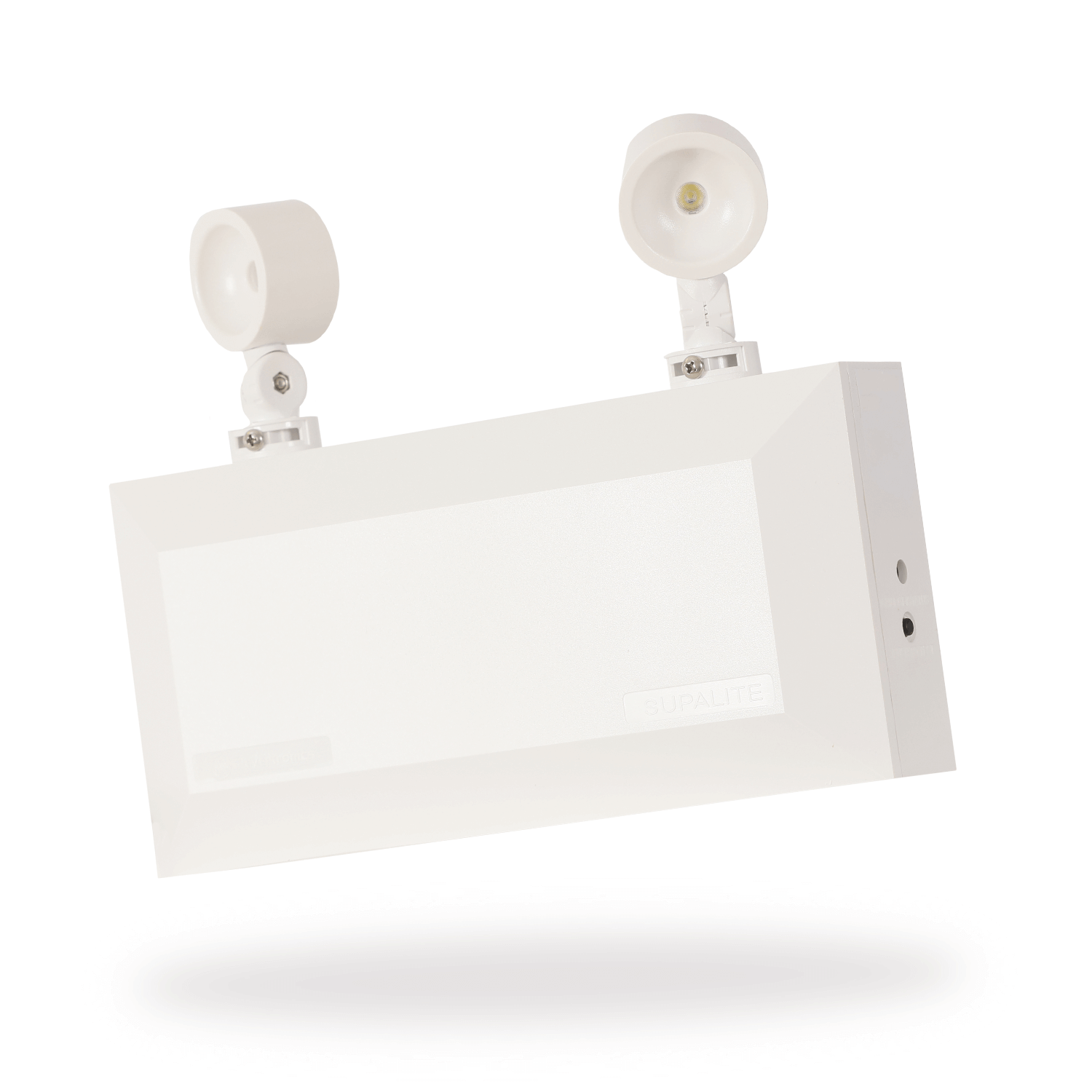

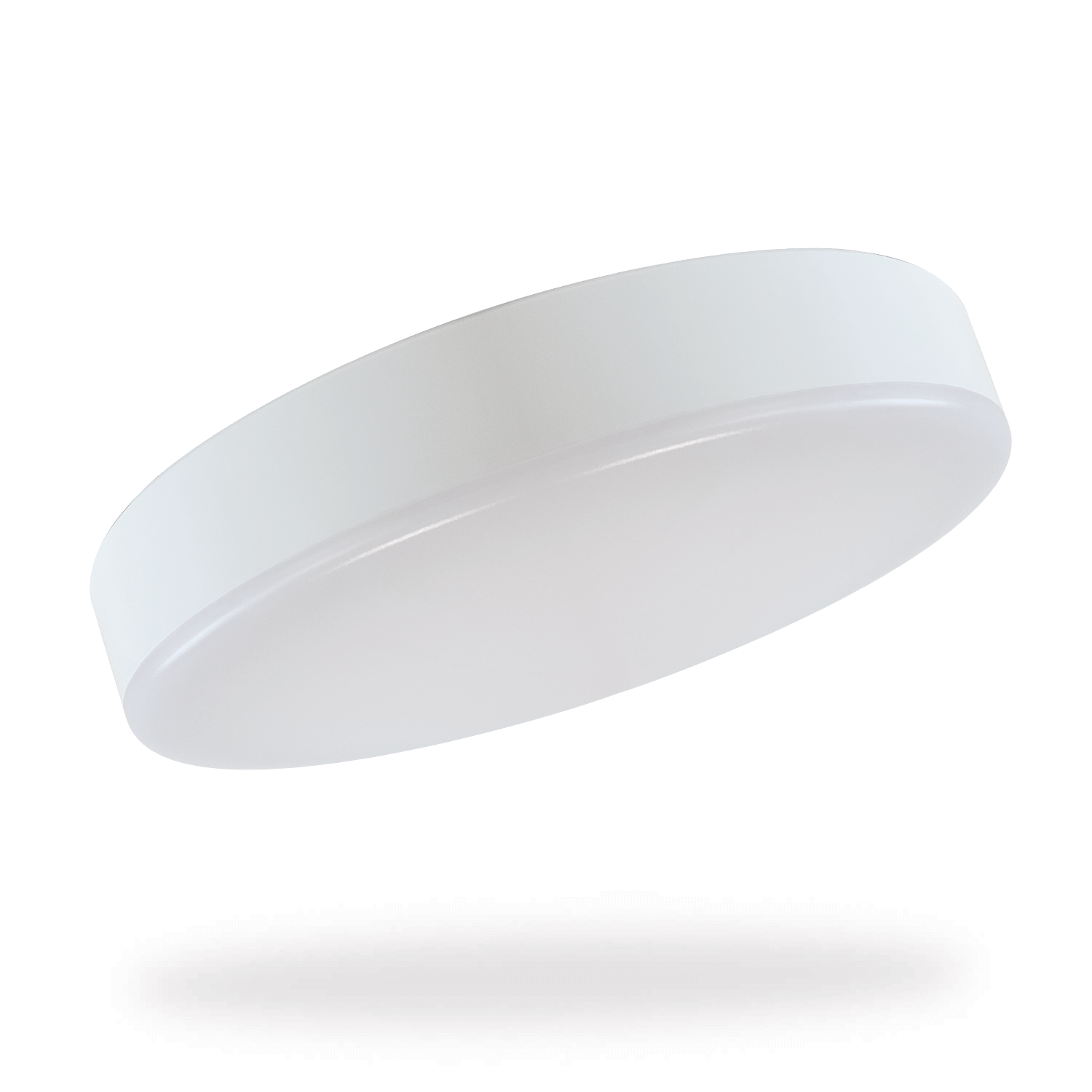

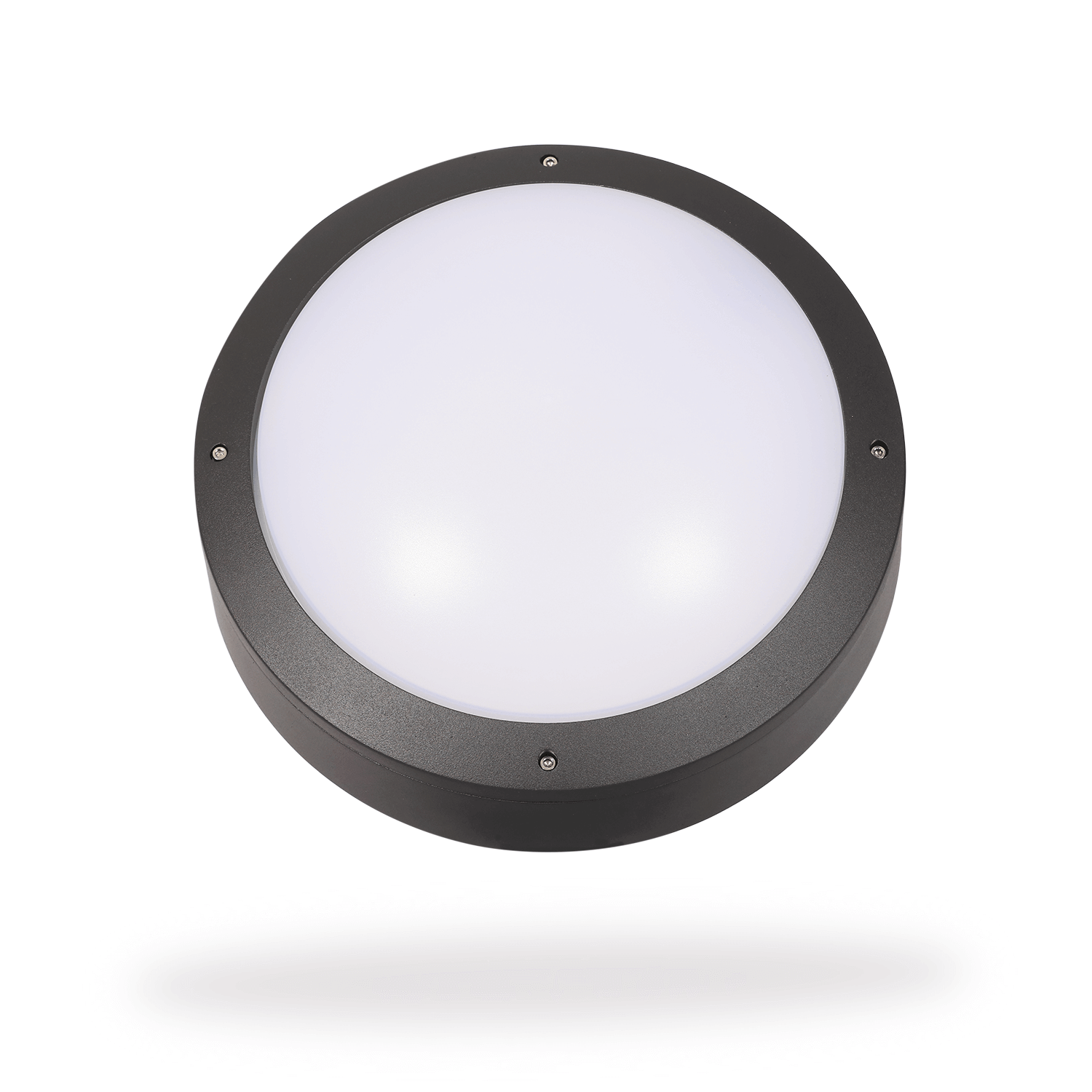

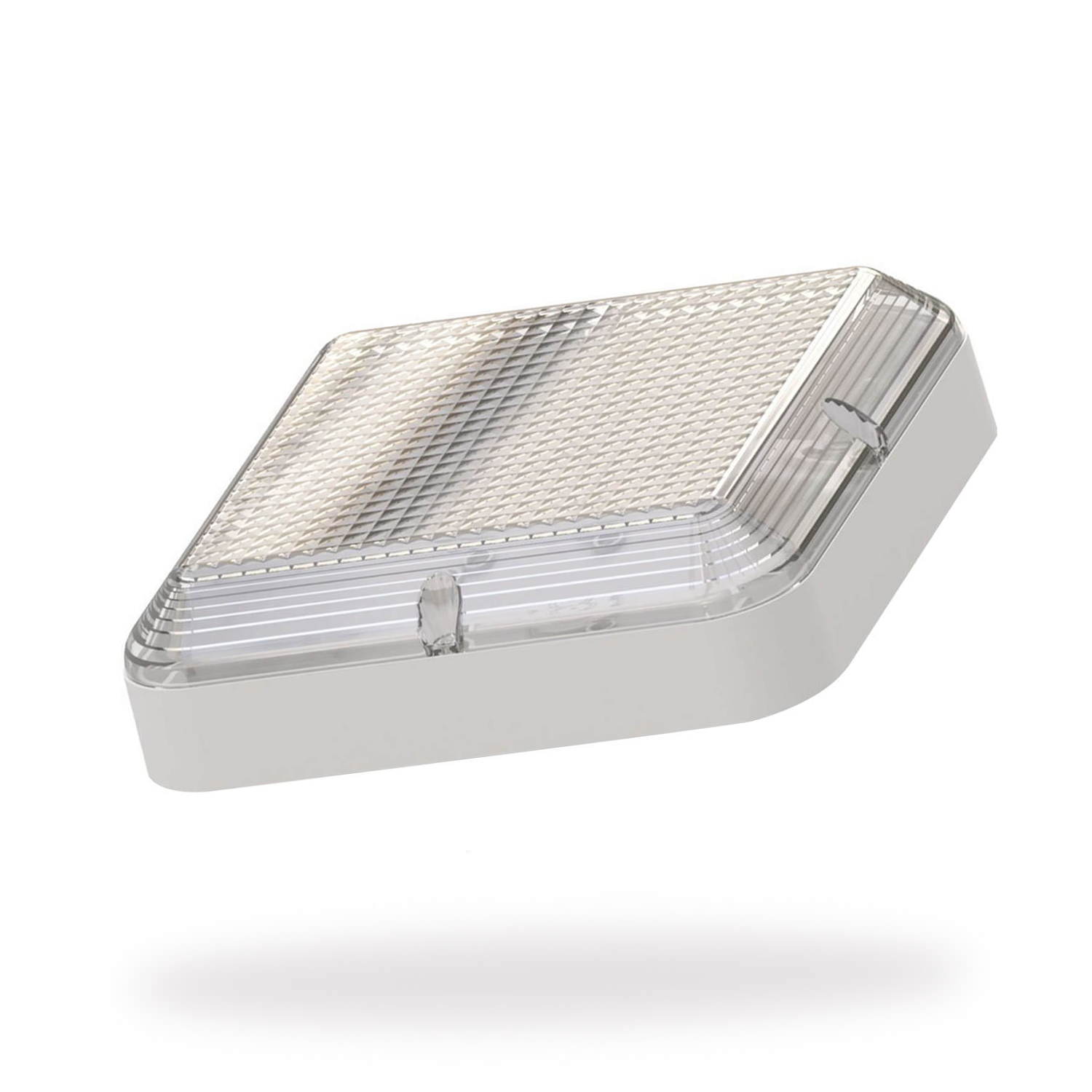

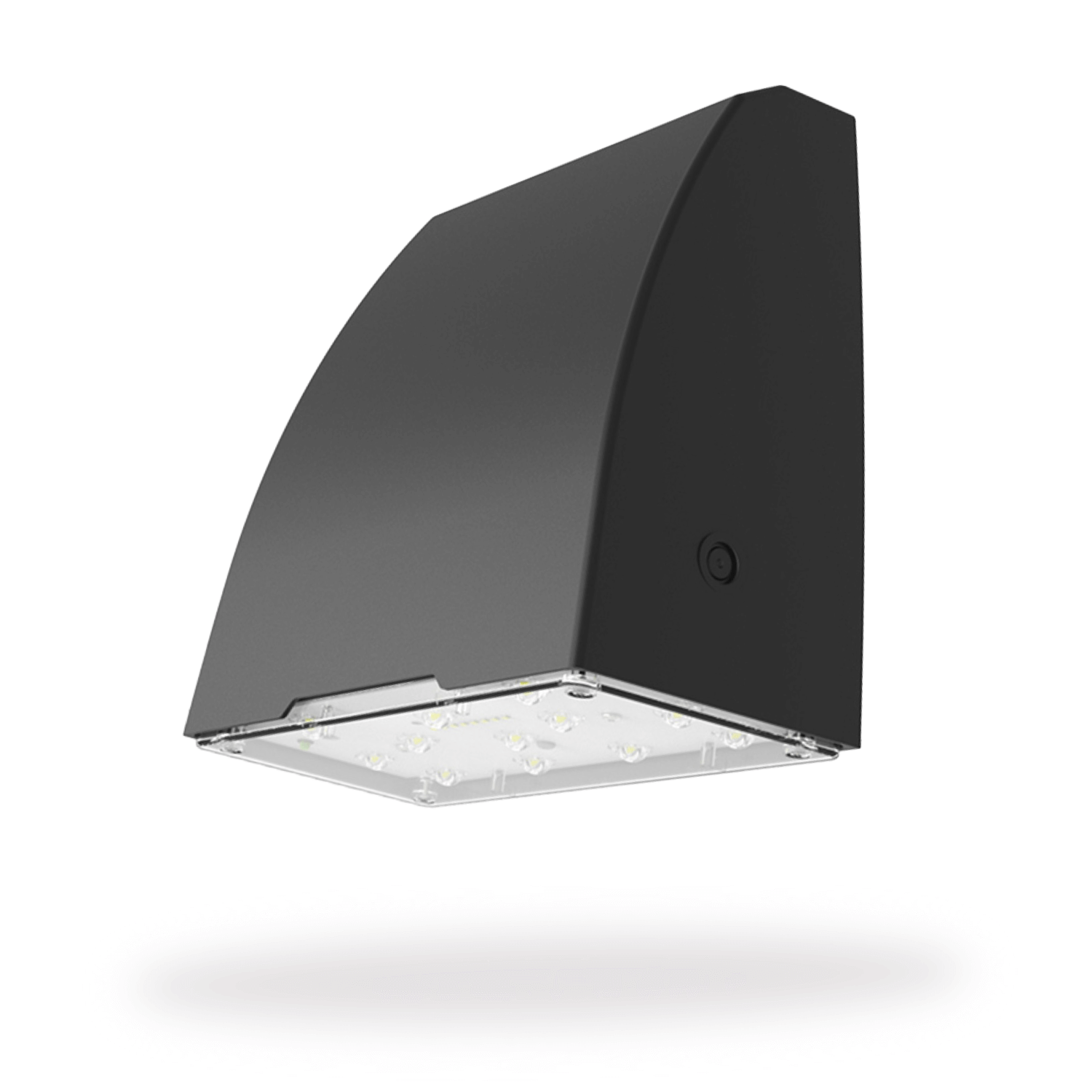

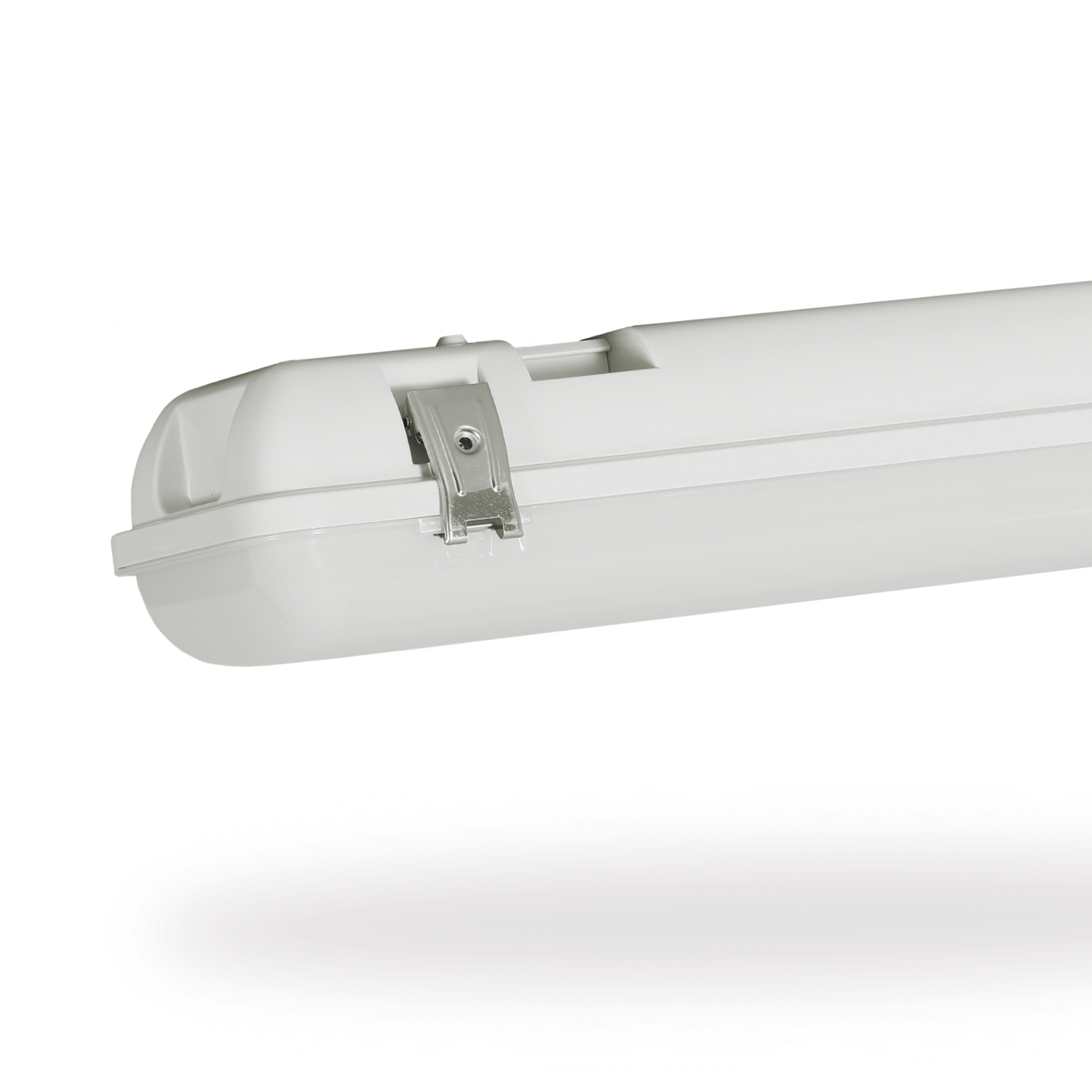

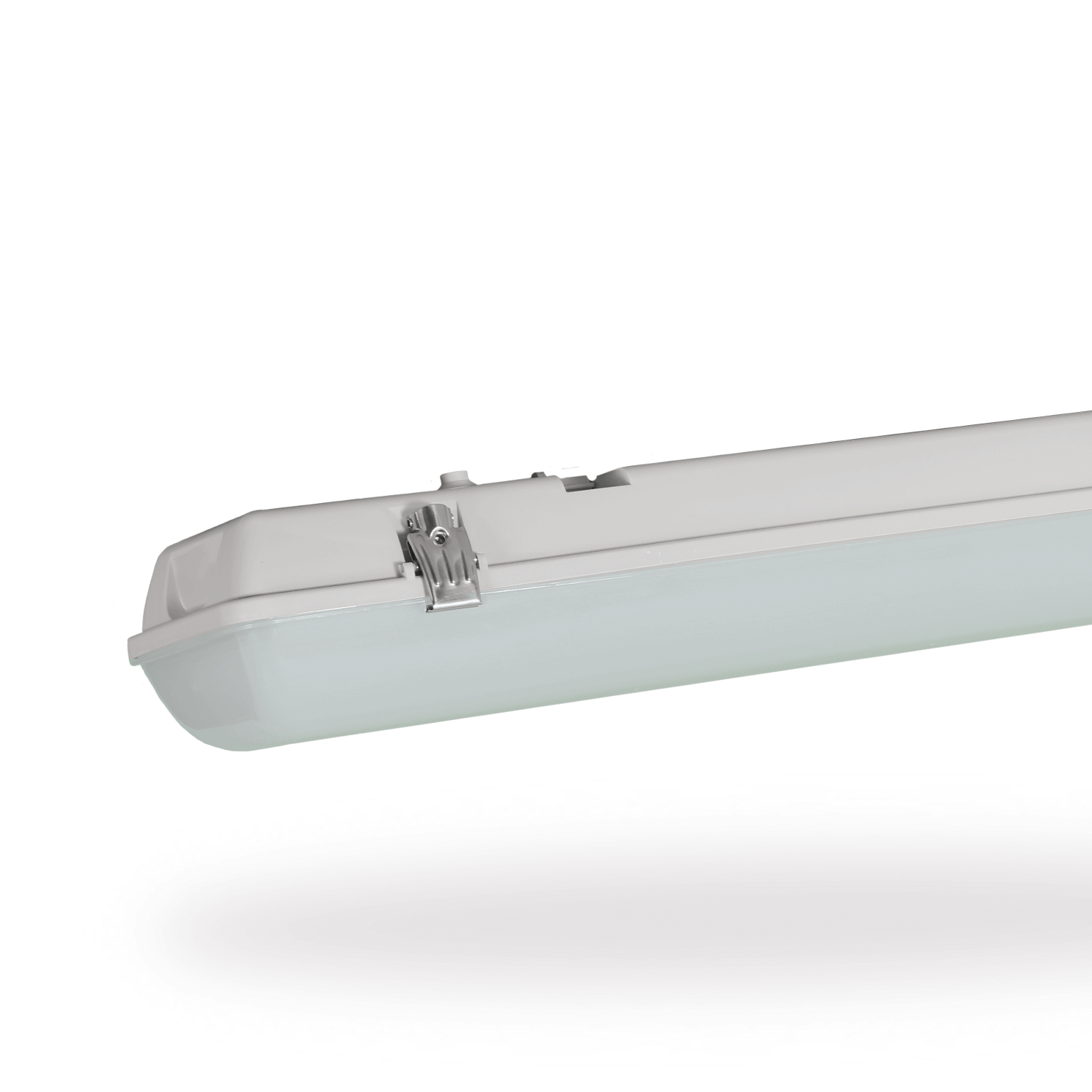

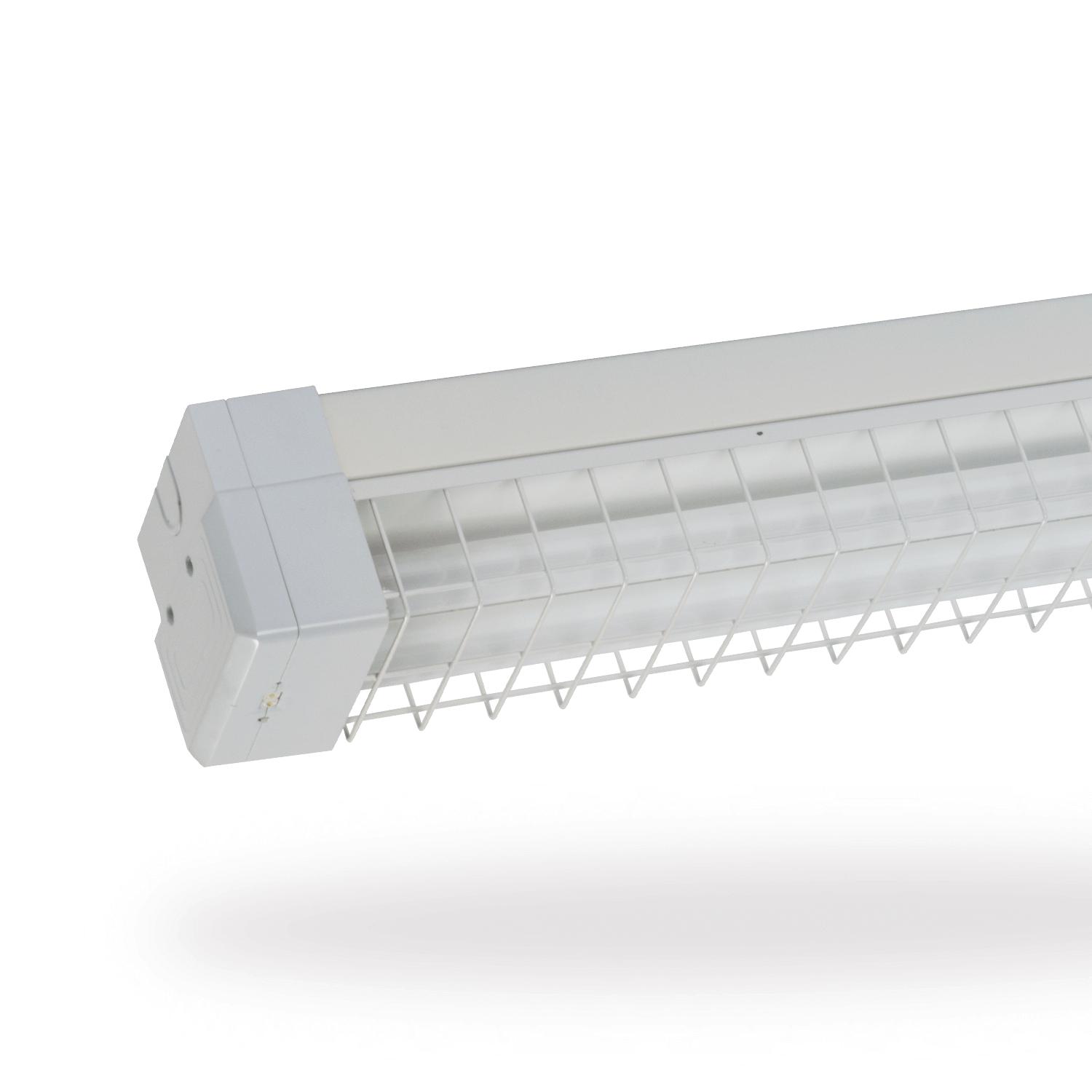

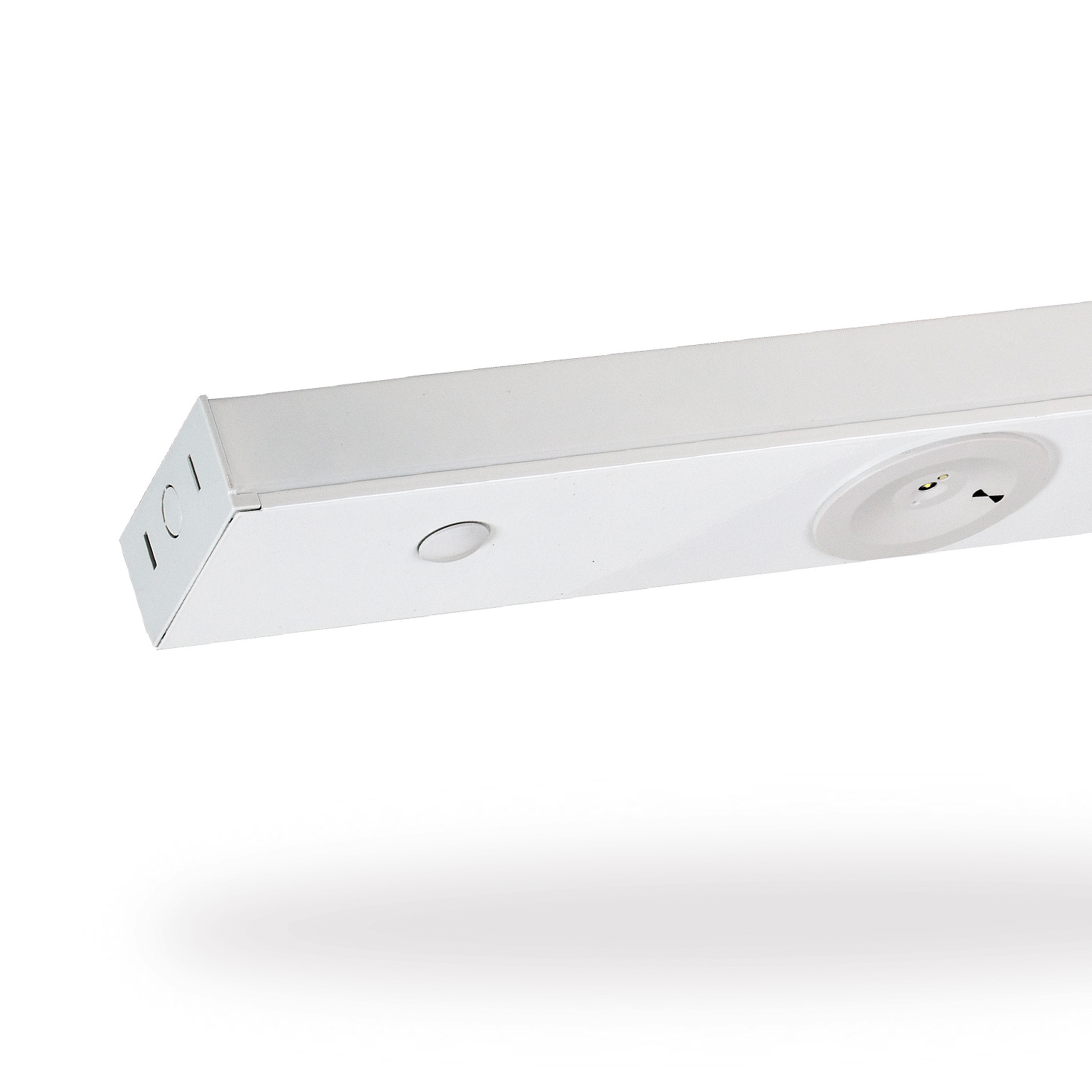

The L10 Optimum Nanophosphate® range is available in Exit and Emergency Luminaires and a full range of Weatherproof Battens which can be found on our product page.

What is Lithium Nanophosphate?

Nanophosphate® is a registered trademark for a Lithium Iron Phosphate battery technology that maximises the performance of the standard technology. The three main areas where Lithium Nanophosphate has distinct advantages over other Lithium Iron Phosphate batteries are listed below.

Power

Nanophosphate is a positive electrode material of remarkable rate capability, critical to high power systems. High power products are able to pulse at discharge rates as high as 100C and deliver superior power by weight or volume in a cost-effective solution. With their low impedance and thermally conductive design, high power cells can be continuously discharged at a 35C rate, a marked improvement over other rechargeable battery alternatives, and have consistent power over wide state of charge (SOC) range

Safety

Safety begins with chemistry and Nanophosphate is stable chemically, which provides the foundation for safe systems while meeting the most demanding customer requirements. Multiple layers of protection are employed at the chemistry, cell and system level to achieve an energy storage solution with superior safety and abuse tolerance compared to metal oxide lithium-ion chemistries.

Life

Nanophosphate technology delivers exceptional calendar and cycle life. At low rates our cells can deliver thousands of cycles at 100% depth of discharge (DOD), a feat unmatched by most commercial lithium ion cells. Even when cycled at 10C discharge rates, cells deliver in excess of 1,000 full DOD cycles. Not only does the technology retain its energy, it also retains its power capability.

Not all lithium-ion technologies behave the same. The nanoscale structure of the Nanophosphate chemistry, for example, enables battery systems with higher power, increased abuse tolerance, longer life and the greater ability to maintain consistent power over a wide range of state-of-charge (SOC) as compared with competing lithium-ion and other chemistries. Understanding the fundamental chemical differences between Nanophosphate and other technologies is necessary to develop a complete and accurate assessment of the optimal advanced battery system that will deliver the best performance for a given application.

At Clevertronics, we also believe that when comparing different Emergency Lighting products, ensure the technology is comparable as not all Emergency lighting powered with Lithium Iron Phosphate batteries will perform at the same level. It is, therefore, critical to ask to see the performance from actual site results to give you the complete story.

There’s a real difference when the results are in!

L10 Nanophosphate advantages

Not all Lithium battery chemistries perform the same. L10 Lithium Nanophosphate® batteries are proven in the field and matched with long life electronics and LED’s.

The Lithium Iron Phosphate battery technology has been available for over 15 years. However, significant technological breakthroughs in the early-2000s by leading manufacturers of these cells has provided the advanced properties which now sees this as the battery technology of choice for such applications as electric cars, emergency lighting, power drills, and computers. The L10 Nanophosphate range utilises a Lithium Iron Phosphate battery that has significant improvements due to the Nanophosphate advantage.

Clevertronics were global pioneers when they launched the L10 Nanophosphate range of products in 2012 incorporating Lithium Nanophosphate® battery technology which was the world’s first Lithium powered product on the market. The L10 Optimum has proven to be a significant range in the market due to the incredible maintenance savings that have been realised. The range is comprehensive and covers Exit and Emergency luminaires as well as a full range of Battens so you can ensure the facility can take full advantage of the savings available.

Since launch over one million, L10 Nanophosphate fittings have been installed into 100’s of sites across Australia and NZ including, Melbourne Cricket Ground, Perth Children’s Hospital, Barangaroo Reserve, Legacy Way Tunnel and Etihad Stadium, and on-site real world results are exceeding bench-test performance predictions by a significant margin. Clevertronics Zoneworks XT monitoring system provides unprecedented visibility into on-site product and maintenance performance which is information that assists facility managers achieve compliance and helps Clevertronics in our drive for further innovation.

Together with over 10 years of bench-testing data at elevated temperatures and on-site “torture testing” with specific trial-site partners, Clevertronics has cemented its position as the world leader in lithium powered emergency lighting with its L10 range powered by Nanophosphate technology.

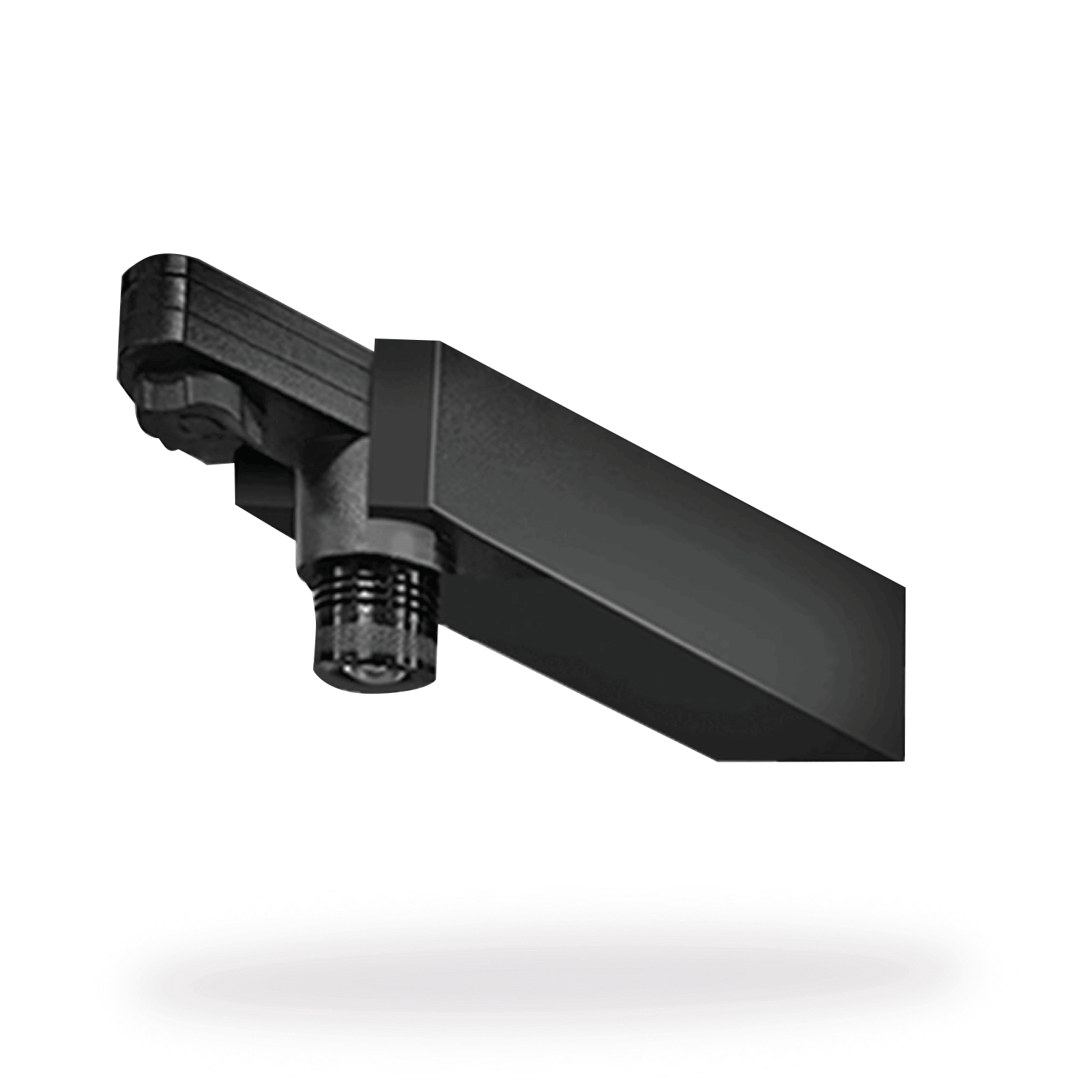

To understand the challenges of incorporating an LFP battery into an Emergency light and why long term testing and making it work in harmony with the total product is vital to ensure long term reliability, Michael Duce – National Systems and Engineering Manager from Clevertronics, provided some insight. “When we were embarking on this project we knew the reliability of the product was centered around the impact heat would have on the components inside the emergency luminaires so we put significant resources into redesigning products to place batteries away from heat sources. In the case of batten luminaires, we developed a thermally isolated section or POD at the end of the batten to house the LFP battery and the emergency LED light source.

Testing was rigorous and Michael and his Australian-based team spent over two years testing the product before it was released on the market in 2012. Michael adds further details about managing the project.

“The second challenge was to ensure we could incorporate the battery into the various range of fittings. Our customers needed a complete range of Emergency, Exits and Battens fittings for their projects and to realise the 80% plus maintenance savings from the L10 range we needed to deliver the entire range as a package. This was challenging from an engineering perspective due to the massive scale of the development task given the large number of different products in our range. It meant that we had to structure the development team to work on several product families concurrently and work very closely with the Production Team to ensure a smooth transition to full-scale production. To see the results now provides great satisfaction especially being the global innovators”

When it comes to lowest ownership costs, there is L10 – and then there is the rest.