Emergency lighting and exit signage are not just regulatory requirements - they are life-saving systems.

For fire contractors, understanding and applying AS/NZS 2293 standards is essential to ensure safety and avoid costly compliance failures. This guide simplifies the process into actionable steps.

Why Compliance Matters

Non-compliant emergency lighting can lead to failed audits, increased liability risks and most importantly, compromised safety during an emergency. AS/NZS 2293 sets the benchmark for design, installation, maintenance, and testing of these systems across Australia and New Zealand.

1. Know the Standards

AS/NZS 2293 is divided into three parts:

- Part 1: System design, installation, and operation

- Part 2: Routine service and maintenance

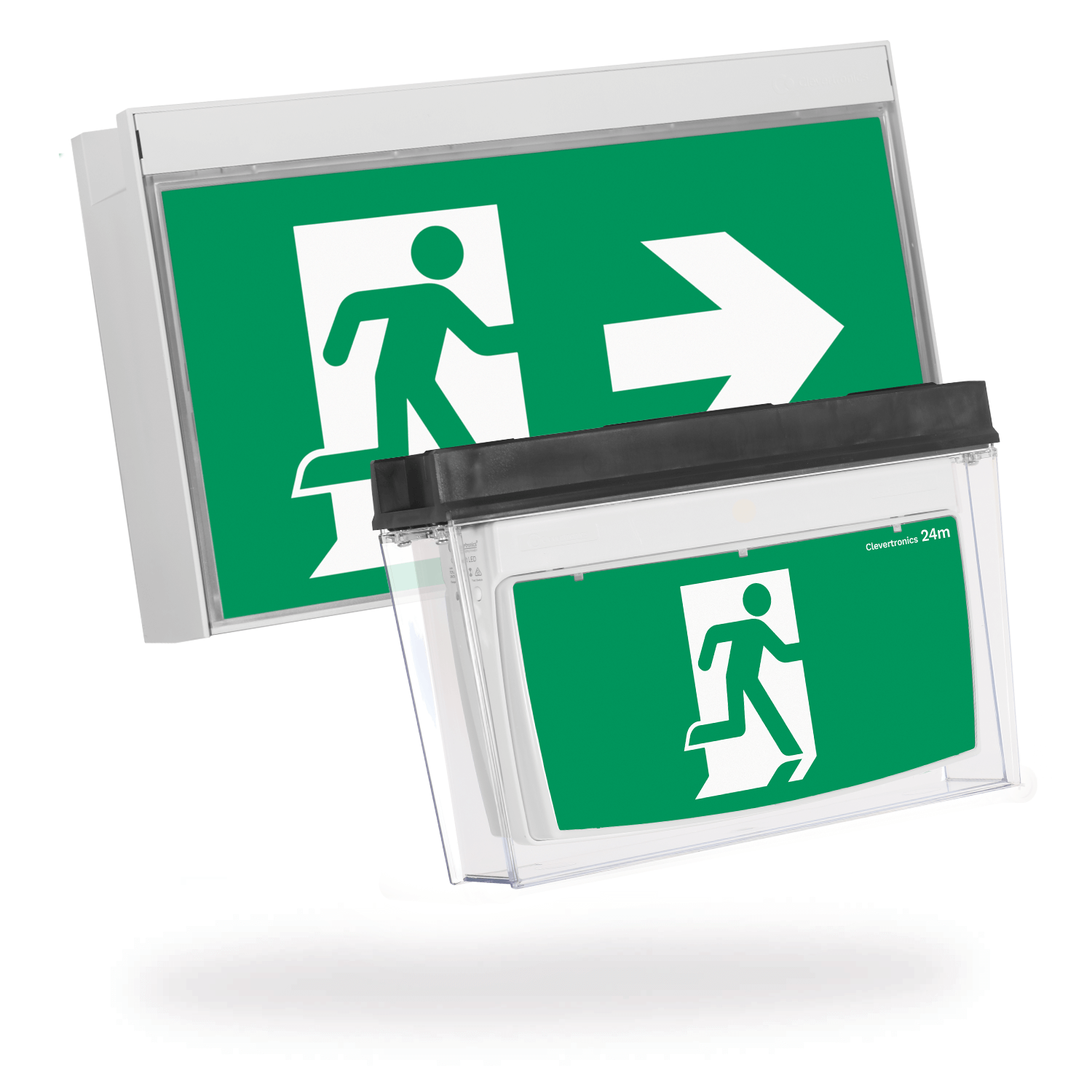

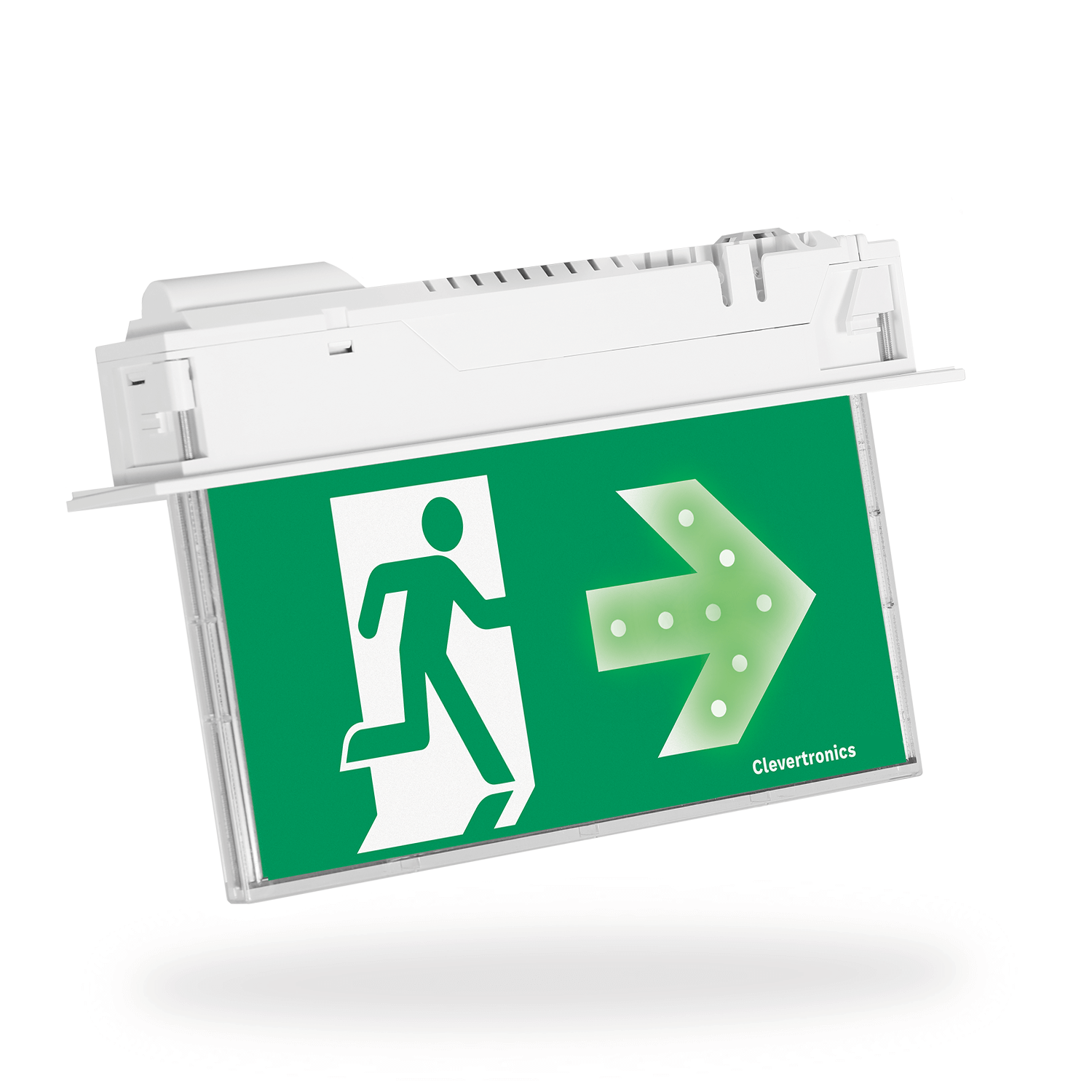

- Part 3: Emergency luminaires and exit signs

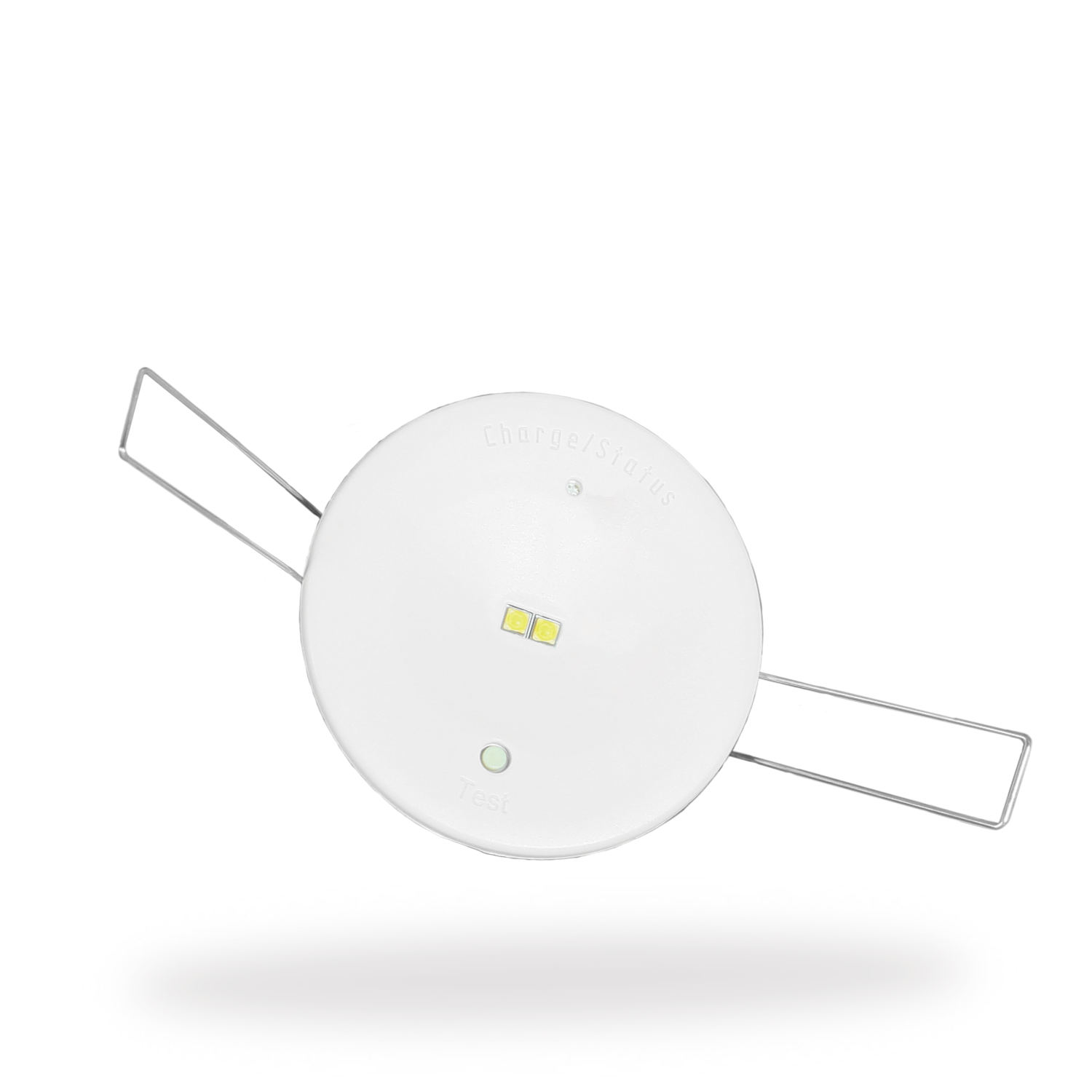

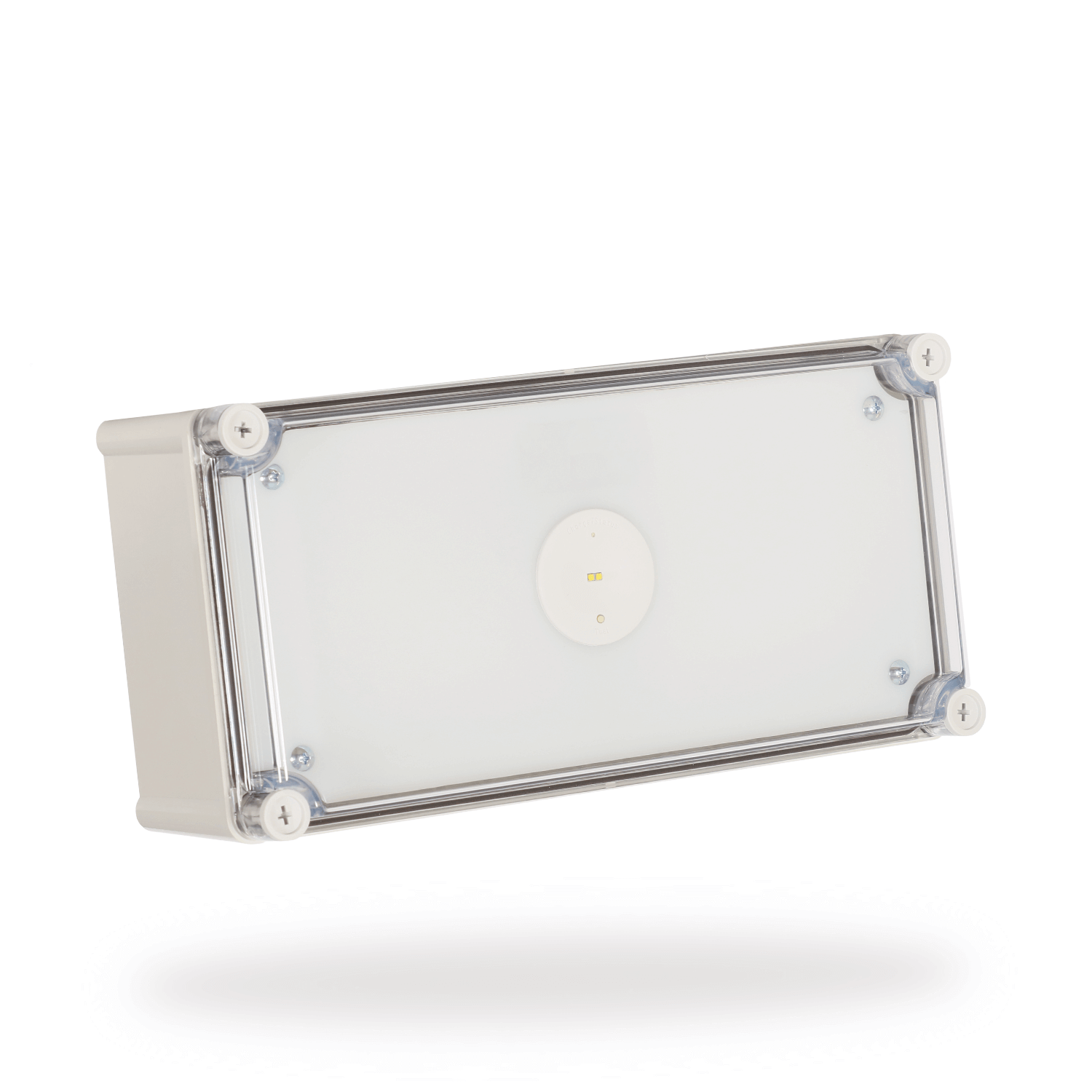

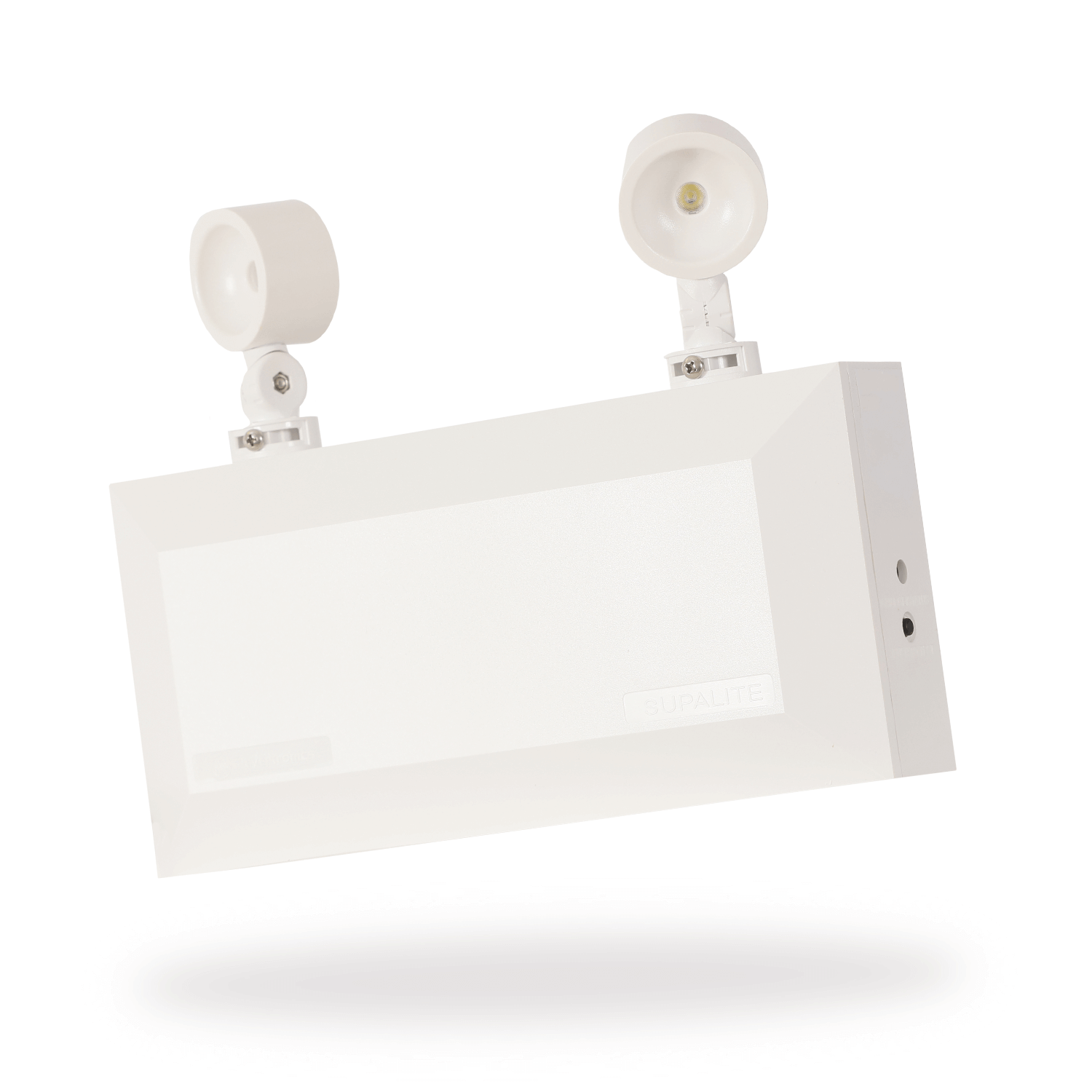

For contractors, Parts 1 and 2 are the most relevant. They outline how systems should be installed and maintained, including inspection and testing procedures. As a specialist manufacturer of exit and emergency lighting, Clevertronics ensures all their products meet Part 3 requirements, so you can trust in their compliance.

2. Maintain Monitored Systems Correctly

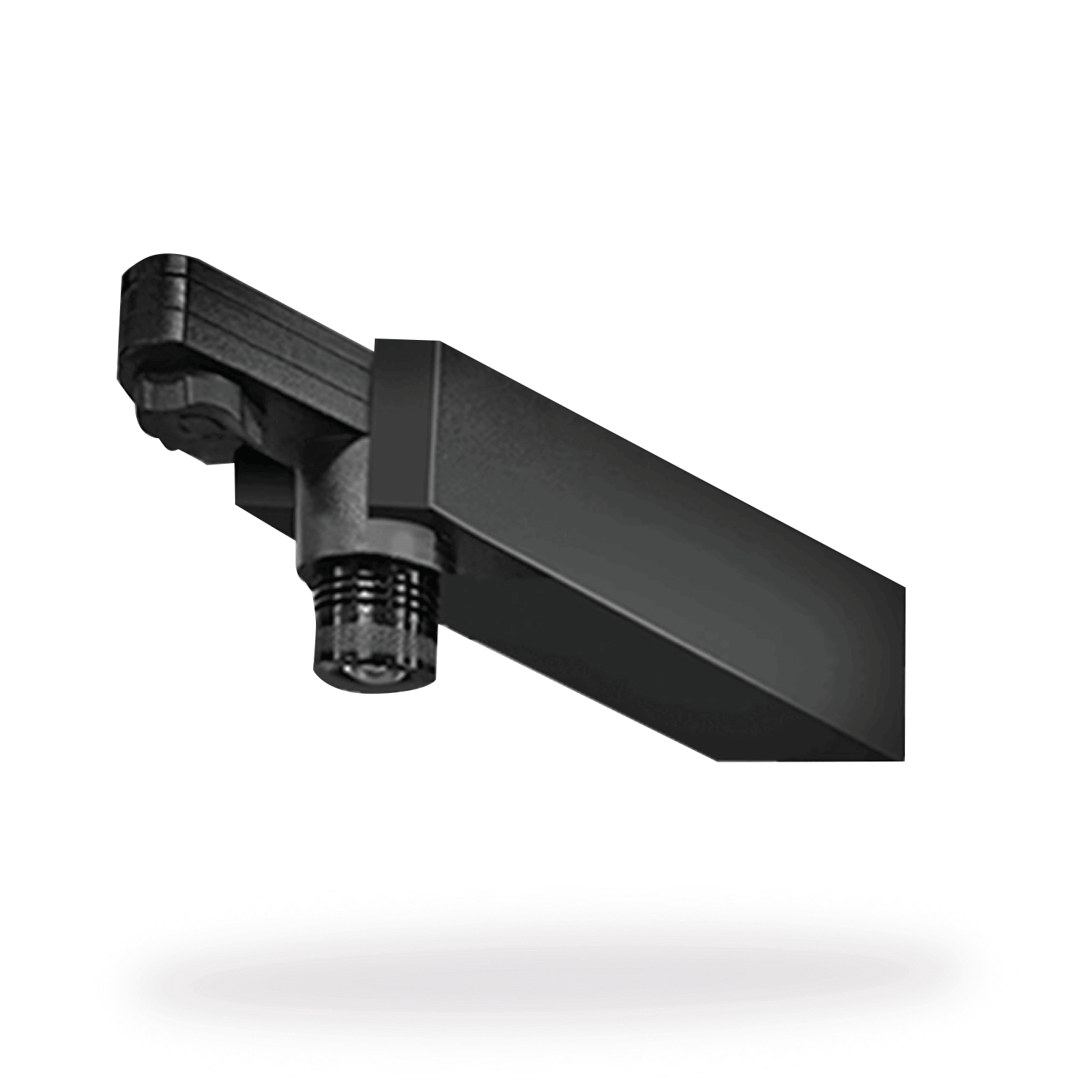

Monitored self-testing systems like the popular Clevertronics Zoneworks platform automate compliance reporting and testing. However, replacing a monitored fitting with a standard one will cause system errors and potential compliance failures.

Best Practices:

- Check system compatibility before replacing fittings

- Check product codes or switchboard labels to confirm monitored systems

- Contact Clevertronics for support and guidance on Zoneworks maintenance and selecting compatible fittings to maintain functionality

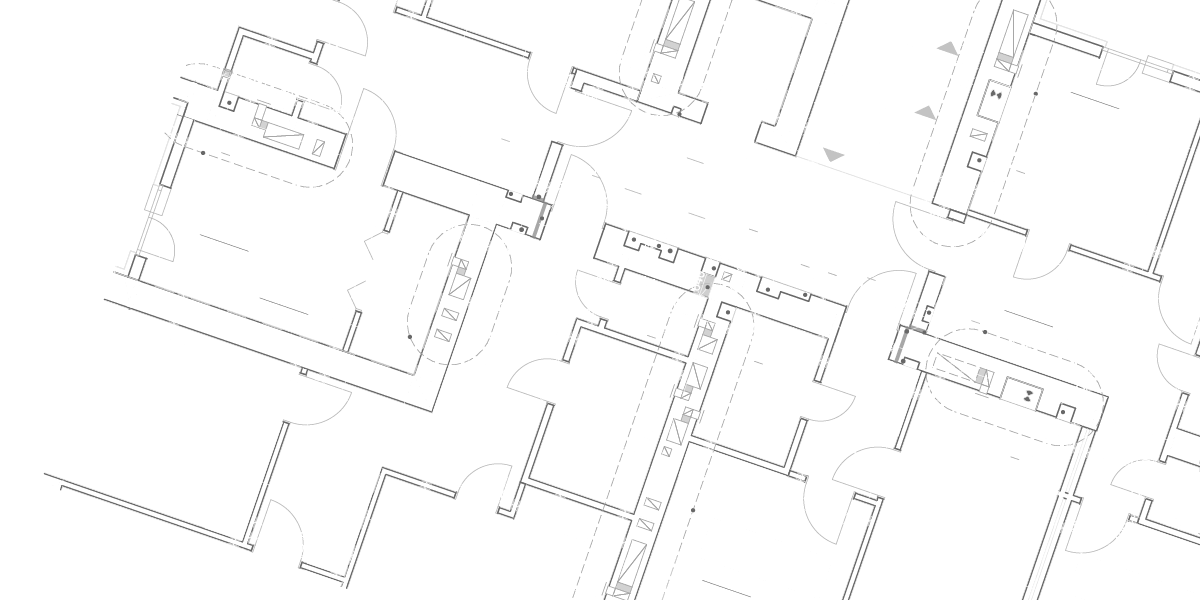

3. Keep Accurate Baseline Data

Baseline data is the foundation of compliance. It includes:

- Up to date register of each fitting's unique ID (e.g., EX1, EM22)

- Logbooks (digital or manual) detailing locations, install date, and expected lifetime of each exit and emergency light fitting

- Correct labelling of devices controlling emergency lighting including MCB's and test switches

Without this data, audits become difficult and maintenance records unreliable.

4. Perform Regular Testing

Appendix A of AS/NZS 2293 Part 2 lists mandatory tasks to be conducted every 6 and 12 months:

- 90-minute battery duration test (manual or automated)

- Inspect for any damage, deterioration, and obstructions to signs and luminaires

- Verify exit signs point people to correct egress paths

- Cleaning of luminaires (dust, dirt, insects)

- Replace failed fittings and update records

Tip: Automated systems like Zoneworks simplify these tasks and reduce reliance on human activity to conduct tests.

5. Records and Reporting

Compliance doesn’t end with testing—it requires documentation retained for 7 years. Keep:

- Duration test reports

- Pass/Fail inspection logs for each luminaire

- Maintenance records showing repairs and replacements

Digital reporting systems make this process faster and are more accurate than manual logbooks.

Common Pitfalls to Avoid

- Installing non-compatible fittings in monitored systems

- Missing baseline data or incomplete records

- Ignoring site or building changes that affect egress paths

- Failing to update logbooks after maintenance

Simplify Compliance with Clevertronics

Clevertronics offers solutions designed to make compliance easy:

- Zoneworks monitored systems for automated testing and reporting, for single sites or across multiple locations

- Lithium battery technology for longer life and reduced maintenance

- Trade Series products for cost-effective installations